Machined parts come in a diverse range of shapes and sizes, and flexible 3D metrology tools for part inspection and dimensional analysis are required to verify their accuracy and quality.

Many machine shops are now equipped with portable CMMs from FARO, such as measuring arms and laser trackers. These meet a variety of dimensional measurement needs, such as on-machine and in-line inspection and CAD comparison, to ensure proper tolerances are achieved.

Croatian innovation from clay to metal products

EKO MEĐIMURJE d.d. uses the FARO devices for quality control in manufacturing. In particular, using the FARO Laser Tracker ION is used for parts alignment and saves 5 hours of production time per day on a capital intensive SHW milling machine.

Many articles have been written highlighting the revolution from bricks and mortar businesses to online shopping, but this is a story of a company that developed a brick that saves mortar, and then reinvented itself to become a metal products manufacturer with a global client base. It is a story of Croatian innovation.

The common thread in the activities of EKO MEĐIMURJE d.d. is making things better by making them simpler – that’s why they created interlocking oversized house bricks, which save clay, mortar and brick-laying effort. Besides the brick-making plant, the company also has a retail home and garden centre. But when the real estate crisis hit Europe, EKO MEĐIMURJE d.d. wasn’t caught off-guard.

Having developed their own engineering capabilities to update their brick plants, they already had relationships in other industries and an active development department working on new ideas in the area of metal work and machining. Today, EKO has renowned global players like Liebherr, Caterpillar, Wirtgen and Komatsu on their customer list.

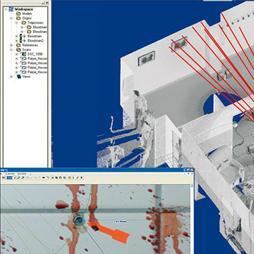

Zoran Zdolec, Manager of electrical facilities at EKO MEĐIMURJE, explains “We use ProEngineer CAD software to design the product in accordance with the customers requirements. Then we use modern metal forming tools to create all the parts.” EKO recently invested in two FARO devices, a Laser Tracker ION and a FaroArm Fusion accompanied by FARO CAM2 Measure 10 software and three weeks of training with Filip Donlic from Teximp d.o.o.– the FARO reseller for Croatia, Bosnia and Serbia. “Thanks to this investment EKO now has the latest in measuring tools for quality control and product documentation.”

Besides the documentation and quality control uses, EKO made one ROI calculation that really contributed to the investment decision. EKO has a SHW milling machine that is used for large parts. The milling head was equipped with a Renishaw measuring head. When parts were being aligned prior to machining using the Renishaw head, the machine is at a standstill and this process could take up to two hours for a very large part.

Filip Donlic was visiting the factory and saw that there is enough room on the machine table to begin alignment of a second part while the first part is still being milled. He recommended a FARO Laser Tracker ION for this process. “By overlapping the process of parts alignment and part milling, EKO is now saving around five hours of production time per day on this capital-intensive machine,” explains Donlic with satisfaction.

![]()

The FARO ION is now used to ensure that each part is perfectly aligned with the machine axis while another part is being finished. Once the milling head is free, the Renishaw can be used to collect a couple of reference points, but this only takes a couple of minutes.

The SHW machine operators are not metrologists, and they work in pairs in three shifts. So the solution had to be very simple to learn and to use: Donlic created an in-software app in CAM2 Measure 10. Now operators can simply follow the on-screen instructions and reference points on the edges of the piece until the app approves the position that has been set.

EKO also uses a FaroArm Fusion for general quality control tasks on its own or in conjunction with the Laser Tracker ION when checking large parts or on parts where features obscure the laser line of sight.

FARO Gage guarantees the conformity of LUSSAULT’s parts

Lussault measures the geometry of parts very precisely using a FARO Gage measuring arm, guaranteeing that no problems arise during assembly.

For decades, measuring columns, callipers and micrometers allowed Lussault to fulfil its inspection needs. Until last year, that is, when the company received an order for a new type of part that was larger and more complex: 300mm in diameter and 350mm in height. The existing inspection methods were no longer enough; their measurement ranges were too small. In addition, they did not allow for theinspection of planarity, perpendicularity and angles of inclination of surfaces as required by these new parts. “We therefore looked for a measuring method to fulfill these requirements. We also wanted to rethink our approach to inspection. Since the parts were larger and therefore heavier, we wanted to implement an on-site inspection solution that didn’t require the part to be removed from the machine”, remembers Gérard Lécrivain, Head of Machining at Lussault. It must be said that when a heavy part that has been moved to the inspection room has to be “retouched”, it isn’t always easy to reposition it identically on the machine and right there is a potential source of errors…

The measurement arm quickly proved itself to be the best solution. Lussault had discovered it at a trade show and, by chance, FARO had demonstrated it on site a few months before the new need had arisen. “The technical solution which was presented met our expectations. Furthermore, we were won over by the ease of use of the arm. The attention paid to our problem by FARO’s technician, as well as his availability, did the rest,” explains Lécrivain. Two technical managers from Lussault were trained by FARO to use the Gage measuring arm and the CAM2 GAGE software. Whenever a new production project presents itself, one of these managers trains the workshop employee who will be using the arm.

The use of the arm fulfils Lussault’s expectations and its applications exceed its initial use. It is in use wherever complex measurements must be taken in locations that are inaccessible to traditional measurement methods, for example for inspections of coaxiality or the angle of inclination of planes. Thanks to sample parts, it is also possible to ensure that the machine tools are set correctly and to begin series production in the certainty that each part will fit into the intended assembly without any problem. “If we didn’t have such a tool, we would have to check, part by part, that the assembly was correct in order to carry out any required adjustments”, explains Lécrivain. Naturally, the time savings are significant…

Jackson Jonson Enterprise Builds Custom Services Using the FaroArm

“Jackson Jonson Enterprise was started with the FaroArm in mind; we have custom-built the service we offer to the public around the capabilities we have gained. Because of how new we are, we haven’t so much replaced a process with the FaroArm as hit the ground running offering services not possible without the FaroArm,” says Bradley Smith, Jackson Jonson Enterprise’s General Manager.

the FaroArm as hit the ground running offering services not possible without the FaroArm,” says Bradley Smith, Jackson Jonson Enterprise’s General Manager.

Jackson Jonson Enterprise (www.jacksonjonson.com) is an independently-owned, design and fabrication company based in Austin, TX,offering product design, development and manufacturing services to a wide range of clientele including manufacturers, wholesalers, entrepreneurs and individuals. Specializing in reverse engineering, design, CAD and prototyping services, Jackson Jonson works with their clients to take any idea from the “cocktail napkin” stage to ready-for-market products.

As an integrated partner in the product development process, Jackson Jonson has expanded its capabilities over the course of the past year to include digital design, product description, precision measurement and rapid prototyping capabilities for the widest range of products possible. Using a custom tailored product development cycle consisting of four stages for each of its clients (Discovery, Feasibility, Definition,

and Execution), Jackson Jonson provides assistance in all aspects of the development process from drawing, modeling, materialspecification, project research, planning and

budgeting, to patent process guidance, marketability planning, and production.

Problem

Jackson Jonson recently acquired Air Force One Performance Industries, an automotive accessory manufacturing company with several lines of air intake products. As a growing company with a focus on providing clients with the best products and designs possible, the company knew they needed to equip themselves with the latest hardware and software. They wanted a CMM solution that would ensure that product quality was up to par with their new acquisitions, as well as provide them with a flexible, easy-to-use solution for reverse engineering and modeling of existing parts.

Solution

After comparing multiple products, the decision was made to purchase the FARO Edge ScanArm. As the latest generation of the FaroArm product line, the Edge improves production, quality, and reverse engineering processes by rapidly verifying or scanning parts with confidence and accuracy. The first ever “smart arm”, the Edge features an integrated personal measurement assistant that revolutionizes portable metrology by providing stand-alone basic measurement capability through its built-in touchscreen and on-board operating system.

The addition of the FARO Laser Line Probe allows Jackson Jonson to significantly increase scan coverage without sacrificing accuracy, providing exceptional speed and feature definition. “From the purchase of the product through training, and even troubleshooting simple software tasks with customer service, implementing our FARO system has been very straightforward,” says Bradley Smith, General Manager of Jackson Jonson. Primarily used for drawing mounting points and maximum tolerances in automotive applications, Jackson Jonson utilizes the FARO Edge along with CAM2 software to measure 3D spaces and objects quickly, easily and accurately.

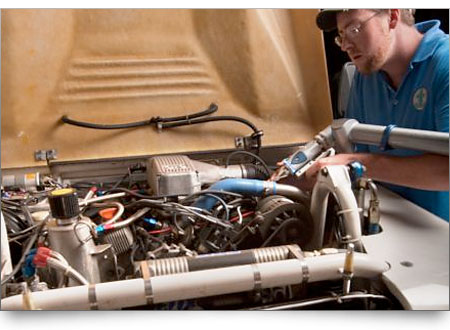

Jackson Jonson uses their Edge to measure the engine enclosures of vehicles for Air Force One Performance Industries intake products. This allows them to gather the critical dimensions in a digital format before they ever undertake a kit development. “By calculating the envelope in 3D space that we can fit our part into, the FaroArm allows us to build parts that fit the first time,” adds Mr. Smith. The portability, automatic reporting, and accuracy are key features that they rely on. Additionally, the Jackson Jonson team utilizes the Edge to measure bent stainless steel tubes that are used in the Air Force One Performance Industries’ automotive cold-air intake kits.

The Edge has allowed them to quickly find the centerline bend radii on the tubes, as well as quickly model the assemblies with accurate hole placements, weld-on attachment placements, etc. As the most cost-effective solution among its competitors, the Edge provides Jackson Jonson with the versatility and flexibility they were looking for, in addition to a simple learning curve for new users. The portability of the device and the compatibility with various software platforms has helped Jackson Jonson to quickly gather precision measurements in any number of locations.

Return on Investment

Jackson Jonson has always looked for solutions to simple problems through creative applications of materials, design techniques, and fabrication methods. By integrating the FARO Edge into their toolkit, the team has found that nearly every project they take on starts with some use of the FaroArm. Used in applications such as dimensional analysis, CAD-based inspection, prototype inspection and comparison, alignment in machining processes, and reverse engineering, the Edge has enabled Jackson Jonson to meet their customers’ 3D measurement requirements whenever and wherever they need them. “Jackson Jonson Enterprise was started with the FaroArm in mind; we have custom-built the service we offer to the public around the capabilities we have gained. Because of how new we are, we haven’t so much replaced a process with the FaroArm as hit the ground running offering services not possible without the FaroArm,” says Mr. Smith.