Fragile, complex and free-form surfaces can be captured as a dense and detailed 3D point cloud by the FARO ScanArm and Laser Scanner, allowing users to perform non-contact, 3D inspections with ease.

Non-contact 3D scanning from FARO can digitize features such as flush and gap that are difficult to inspect with contact methods. Laser scanning for 3D documentation can be a faster method of verifying many features and dimensions and it produces a more comprehensive and easier-to-read report. For as-built documentation it is simply the best show in town.

A special measurement arm for a special bike

Evotech, based in Villa Agnedo (Trento, Italy), purchased the FARO Edgemeasurement arm equipped with the Laser Line Probe and CAM2 Measure 10 measurement software to perform reverse engineering activities, beginning with a project dedicated to a very special motorcycle.

Evotech is a company with an international reach that manufactures special aftermarket accessories and components for sport and naked bikes. Certified engineer Matteo Tisi, the firm’s Research, Design and Production Manager, provides a brief account of the story: “When the company was founded in 2004, it began with the manufacture of standard and decidedly simple components. However, the company’s know-how has grown exponentially over the course of 10 years, and today the Evotech brand is synonymous with technology, style and quality worldwide.”

Particular attention is paid to the development of products that celebrate the concepts of design, functionality and ease of assembly. Evotech is therefore one of the points of excellenceof ‘Made in Italy’ manufacturing, and has been able to raise its technological level by investing a good percentage of its yearly profits in research and development and cutting-edge production facilities. Matteo Tisi continues: “The last step in this development process consisted of implementing a modern rapid prototyping and reverse engineering centre, which makes it possible to immediately progress from idea to product and to create and test several solutions for each new application.”

This is why Evotech chose to invest last summer in a FARO Edge ScanArm, a next-generation portable seven-axis measurement arm equipped with a Laser Line Probe, used for contact and non-contact measurements: this device is the ideal solution to create a rapid interface between activities such as part/CAD comparison, 3D modelling and, of course, rapid prototyping and reverse engineering. Matteo Tisi explains the reason for this decision: “Personally, I had been familiar with FARO instruments for a few years because of my prior experience at university and at Fiat’s centro costruzioni sperimentali (experimental construction centre).

For its part, Evotech became interested in these devices following participation in specialised trade fairs. A very special project was what finally pushed us to purchase the measurement arm.” Tisi explains: “to ‘convey’ to the market our idea of performance and the dynamic nature of our products, we wanted to create a motorcycle, called the Trentino Naked 3, which would be able to achieve exceptional performance on the track.

In the guise of a naked bike, this motorcycle conceals superbike features, dynamic, excellent performance and a supercharged engine with a mechanical centrifugal compressor that is able to achieve extremely high levels of power while retaining excellent driveability on the track. This move, made for promotional purposes one year ago, has been very successful and has introduced our name to a greater number of enthusiasts and sportsmen. More recently, we planned the construction of a second special bike, this time with a greater focus on concepts such as style and design, while also keeping some surprises in store on the technological side.”

For this new endeavour, Evotech is taking inspiration from a vintage model with a modern twist,brimming with cutting-edge technology and ‘Made in Italy’ style. This is part of the reason why Evotech purchased the FARO Edge ScanArm for use in reverse engineering. “Basically,” Matteo Tisi comments, “FARO has made a great contribution by equipping us with technology that can make our ideas a reality.” Of course, Evotech did not purchase the FARO Edge ScanArm for the special bike project only: the new measurement arm will be used by the company for other manufacturing activities, especially in reverse engineering processes. In addition, for the manufacture of items such as frame holders, plate brackets and engine case covers, the Trento-based company will be able to rely on this tool to scan the relevant items and obtain the point clouds needed to capture the sizes, overall dimensions, profiles, etc. before moving on to the actual design phase.

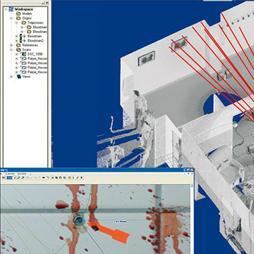

“Every 3D scan is conducted using CAM2 Measure 10 software,” Tisi continues, “which makes our work simple, rapid and flexible, in accordance with various application requirements.” It should also be highlighted that Evotech then loads the data into the SolidWorks software to begin the design phase. The designed part is then 3D printed for the testing phase and, if it passes, production begins.

“In terms of dimension testing,” Tisi explains, “thanks to the precision and reliability of the FARO Edge ScanArm, we believe that we will soon be able to move directly from the reverse engineering phase to production, avoiding the intermediate rapid prototyping phase.”

Matteo Tisi concludes by bringing results and objectives into focus: “We have only been using the FARO Edge ScanArm with the integrated Laser Line Probe and Measure 10 software for a few months, but we can already confirm that this package fully satisfies our needs. The results are already clear: the data acquisition phase is much more exact and precise, production speed has increased and time to market has decreased. This technology is changing the way we conceive of our products and its range of applications could increase significantly.”

Virtual dissection of the human brain with the FaroArm

For nearly three years, several teams at the University François Rabelais of Tours have been working on a project for the virtual dissection of human brain fibres, the Fibratlas project. This multidisciplinary project combines MRI imaging researchers from the INSERM U930 unit, anatomists from the anatomy laboratory of the Faculty of Medicine at Tours and computer scientists from the computer lab at Tours (LI, EA2101). The goal is to generate “ground truth” data in order to confirm the results of algorithms reconstructing brain fibres based on MRI images (tractography).

In the scope of this project, the researchers are conducting a dissection of the two hemispheres of the human brain by stages. The specimens are collected from bodies which have been donated to science. As dissection is a destructive process; it is necessary to preserve a record of each step. As a first stage, they record the results from each step in the dissection of the cerebral hemispheres using a FARO ScanArm laser scanner, and then register these results using common reference points spread on the scanned surfaces. The neuroanatomist then “replays” the dissection virtually in order to identify the visible portions of the fibre bundles at each digitized step. These portions are then used to reconstruct the entire fibre bundles being studied. The results obtained are compared to the reconstructions of the same bundles based on MRI images in order to confirm the tractography methods used in medical imaging.

As the precision of the MRI is in the range of mm3, the research team needed a more accurate 3D measurement system in order to produce an extremely precise digital model of the dissected specimen.

The team selected the FaroArm Fusion 7-axis measuring arm and its ScanArm V2 laser digital sensor to digitize the brains in 3D during their dissection. The brain is treated so that it is firm enough not to be deformed by the dissection. It is then attached to a plate on which the reference points are scanned by the touch sensor. The laser head is then used to digitize the remainder of the sample. The arm offers an unmatched freedom of movement, such that it can be revolved around the sample in order to digitize the entire surface.

“The precision and speed of measurement of the FaroArm Fusion were decisive in terms of the selection of the portable CMM for the scientific team, as the digital sensor is capable of scanning more than 19,000 points per second,” noted Mr Serres, doctoral researcher at the computer lab of the University of Tours. “Furthermore, its small footprint and its manoeuvrability made it extremely easy to integrate into the anatomy laboratory.”

The researchers are now continuing their work in compiling the data and developing the software. The tool created will also serve both as a basis for training neurosurgeons and navigating between the different dissection steps of the brain and as a basis for research work evaluating the results given by diffusion MRI.

About the customer

U930, located at the Teaching Hospital (CHU) in Tours, is composed of 5 teams of researchers and practitioners. The main goal of the team involved in the project is one of creating and confirming imaging methods which can be used in clinical research in order to help understand the physiopathological mechanisms involved in the development and functioning of the human brain.

The LI is composed of computer science researchers, and is particularly interested in creating new methods and improving algorithms and their applications in the medical field. The Fibratlas project makes use of laboratory capacities with regard to 3D data acquisition and interactive scientific visualisation.

State-of-the-Art Measurements for Special Valves

The company’s Quality Manager, Giuseppe Ramponi, explained: “The particularity and geometric complexity of our products require highly specialized production processes and control procedures to ensure compliance with requirements and specifications.” To meet these requirements Petrolvalves has been using a FaroArm Platinum six-axis measurement arm with Measure X software (subsequently updated to CAM2 Measure 10) since 2005. “It is a sophisticated instrument that meets our needs perfectly,” Ramponi added.

With the production of increasingly complex and technological components, and having seen the excellent results achieved using the “old” arm, at the end of 2011 Petrolvalves decided to evaluate the purchase of a second instrument. This device would be used to solve problems related to the measurement of actuators with highly complex geometry, recently produced for undersea valves. Following detailed research and several consultations with FARO, the company chose the FARO Edge ScanArm (i.e. a FARO Edge measurement arm with a Laser Line Probe), equipped with CAM2 Q and Geomagic Qualify software.

Ramponi: “Tests demonstrated that this was the right instrument for our specific situation since it takes fast, precise measurements of geometrically complex components such as undersea actuators, worm-screws, special shafts and grooves.”

In short, the FARO Arm offers a level of precision that is comparable to fixed-coordinate measurement machines. In addition to taking up less space in the workshop, it performs inspections more efficiently and eliminates machine downtime.

In particular, FARO’s new Laser Line Probe gives the FARO Edge new functionality and performance with regard to contactless measurement that would be difficult to match. In fact, the wide laser beam significantly increases scanning capacity without sacrificing precision while ensuring extremely high speed and definition. Without forgetting that it is possible to optimize measurement and scanning operations with the CAM2 Measure 10 software.

Giuseppe Ramponi concluded: “We have only been using the new arm for a short time – it went into operation in January 2012, following the training course – however, we are already using it with excellent results. We have even begun measuring geometrically complex pieces and we are obtaining excellent results in terms of precision, reliability and speed.”

Jackson Jonson Enterprise Builds Custom Services Using the FaroArm

the FaroArm as hit the ground running offering services not possible without the FaroArm,” says Bradley Smith, Jackson Jonson Enterprise’s General Manager.

Jackson Jonson Enterprise (www.jacksonjonson.com) is an independently-owned, design and fabrication company based in Austin, TX,offering product design, development and manufacturing services to a wide range of clientele including manufacturers, wholesalers, entrepreneurs and individuals. Specializing in reverse engineering, design, CAD and prototyping services, Jackson Jonson works with their clients to take any idea from the “cocktail napkin” stage to ready-for-market products.

As an integrated partner in the product development process, Jackson Jonson has expanded its capabilities over the course of the past year to include digital design, product description, precision measurement and rapid prototyping capabilities for the widest range of products possible. Using a custom tailored product development cycle consisting of four stages for each of its clients (Discovery, Feasibility, Definition,

and Execution), Jackson Jonson provides assistance in all aspects of the development process from drawing, modeling, materialspecification, project research, planning and

budgeting, to patent process guidance, marketability planning, and production.

Problem

Jackson Jonson recently acquired Air Force One Performance Industries, an automotive accessory manufacturing company with several lines of air intake products. As a growing company with a focus on providing clients with the best products and designs possible, the company knew they needed to equip themselves with the latest hardware and software. They wanted a CMM solution that would ensure that product quality was up to par with their new acquisitions, as well as provide them with a flexible, easy-to-use solution for reverse engineering and modeling of existing parts.

Solution

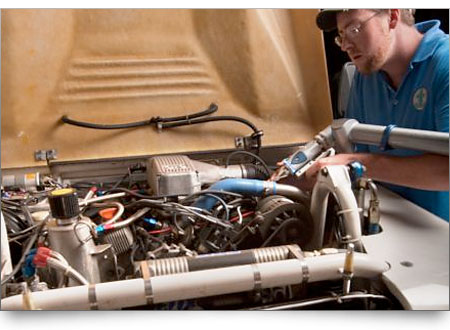

After comparing multiple products, the decision was made to purchase the FARO Edge ScanArm. As the latest generation of the FaroArm product line, the Edge improves production, quality, and reverse engineering processes by rapidly verifying or scanning parts with confidence and accuracy. The first ever “smart arm”, the Edge features an integrated personal measurement assistant that revolutionizes portable metrology by providing stand-alone basic measurement capability through its built-in touchscreen and on-board operating system. The addition of the FARO Laser Line Probe allows Jackson Jonson to significantly increase scan coverage without sacrificing accuracy, providing exceptional speed and feature definition. “From the purchase of the product through training, and even troubleshooting simple software tasks with customer service, implementing our FARO system has been very straightforward,” says Bradley Smith, General Manager of Jackson Jonson. Primarily used for drawing mounting points and

maximum tolerances in automotive applications, Jackson Jonson utilizes the FARO Edge along with CAM2 software to measure 3D spaces and objects quickly, easily and accurately. Jackson Jonson uses their Edge to measure the engine enclosures of vehicles for Air Force One Performance Industries intake products. This allows them to gather the critical dimensions in a digital format before they ever undertake a kit development. “By calculating the envelope in 3D space that we can fit our part into, the FaroArm allows us to build parts that fit the first time,” adds Mr. Smith. The portability, automatic reporting, and accuracy are key features that they rely on. Additionally, the Jackson Jonson team utilizes the Edge to measure bent stainless steel tubes that are used in the Air Force One Performance Industries’ automotive cold-air intake kits. The Edge has allowed them to quickly find the centerline bend radii on the tubes, as well as quickly model the assemblies with accurate hole placements, weld-on attachment placements, etc. As the most cost-effective solution among its competitors, the Edge provides Jackson Jonson with the versatility and flexibility they were looking for, in addition to a simple learning curve for new users. The portability of the device and the compatibility with various software platforms has helped Jackson Jonson to quickly gather precision measurements in any number of locations.

Return on Investment

Jackson Jonson has always looked for solutions to simple problems through creative applications of materials, design techniques, and fabrication methods. By integrating the FARO Edge into their toolkit, the team has found that nearly every project they take

on starts with some use of the FaroArm. Used in applications such as dimensional analysis, CAD-based inspection, prototype inspection and comparison, alignment in machining processes, and reverse engineering, the Edge has enabled Jackson Jonson to meet their customers’ 3D measurement requirements whenever and wherever they need them. “Jackson Jonson Enterprise was started with the FaroArm in mind; we have custom-built the service we offer to the public around the capabilities we

have gained. Because of how new we are, we haven’t so much replaced a process with the FaroArm as hit the ground running offering services not possible without the FaroArm,” says Mr. Smith.

Objective – Leadership in Innovation

The FARO system is equally impressive for taking exterior as for interior measurements in Dingolfing and Regensburg.

FARO has successfully combined three tried-and-tested measuring systems in the Track ScanArm. The mobile measuring system is particularly impressive in the measurementof entire vehicles, not least as a result of its efficiency.

The BMW Group relies on the latest, stateof- the-art technologies, in particular in development and production. In this context, the Track ScanArm from FARO, which is used at the plants in Dingolfing and Regensburg (both in Germany), represents an equally clever and mobile measuring system in Geometric Integration measuring technology. What was required was a system for recording tactile points and surfaces irrespective of location, as well as wireless transfer rather than via a tool. Calibration was therefore not to be conducted by means of reference marks, as this represents an uncertainty factor, for example because of the moving parts. The objective was clearly non-contact wireless transfer – this was the basic requirement of the system to be procured. FARO’s Track ScanArm, which ideally satisfied the requirement profile, was ultimately ordered for the German plants.The Track ScanArm combines the FARO Laser Tracker, the seven-axis FaroArm Quantum with a range of 2.4m, and the Laser Line Probe V3 scanner. The package is completed by Polyworks software. All measuring systems can be linked together by means of a common coordinate system. The coordinate system can be calibrated either by means of the laser tracker, by means of tactile measurements by the FaroArm or through scanned measurements. The coordinate system is then transferred to each of the other systems, for example from the tracker to the arm or vice versa – and thus from any vantage point. As the fixed base, the laser tracker either stands on the tripod as in Regensburg or is hung from the ceiling as in Dingolfing. The coordinate system is transferred from the fixed base of the laser tracker to the arm, irrespective of where it is located in the respective measuring environment. This means that you calibrate and can then carry out measurements – separate from the tracker and without any visual contact – of both the exterior and the interior of the vehicle, with all seven degrees of freedom. Tactile measurements or the scanning of surfaces are ideal for precisely those places that cannot be reached with the laser tracker. The Track ScanArm ultimately combines the advantages of the laser tracker, tactile measuring arm and laser scanner systems, supplemented by powerful software and a computer.

that make up the Track ScanArm individually.

FARO provided a suitable partner for the implementation of this ambitious project for the two Bavarian BMW plants simply because FaroArms have already been successfully employed both in Regensburg and in Dingolfing for some ten years now. The plant in Lower Bavaria alone currently has a wide range of FaroArms from the Gold, Fusion and Platinum series. The initial presentations of the Track ScanArm were carried out as long ago as 2006. The system finally became really interesting for metrologists when FARO was also able to offer wireless vehicle network transfer. Procurement was followed by the installation phase, during which the specialists from both partners contributed their expertise. The Track Scan- Arm has been in operation as planned since mid-2009. In the end, there were several reasons that spoke in favour of the FARO system compared to that of a competitor. These included not only the price but also the fact that the quality experts at both plants were already familiar with the measuring arms and their high level of accuracy. There is also the “monopoly position” resulting from the fact that at the time FARO was the only company able to offer wireless transfer of the vehicle network.

The range of tasks covered by geometric integration is extensive: the focus is on product qualification during the product development stage; or pilot production, in order to get the suppliers’ parts up to series production standard and to ensure that the entire vehicle is ready for production. This is also followed by analysis in the series production process whenever a component cannot be fitted as required. In the course of the measurements required for testing, the Track ScanArm is regularly employed throughout the entire vehicle, on both the interior and exterior, in a very wide variety of ways. The system is furthermore used for checking production tools and jigs. Assembly jigs are currently being measured in Regensburg, so that it will be possible to restore the current status of the C-frames after retooling. In the case of these measurements, the system is particularly impressive not only for its mobility but also for perfect ‘job-sharing’: The measuring arm is used whenever measurements need to be taken in locations that cannot be accessed by the laser tracker. The tracker is used, on the other hand, for measuring points at heights of up 3.0m which cannot be reached with the measuring arm.

The combination of tracker, tactile measuring arm and laser scanner has proven absolute stood the testing in both Dingolfing and in Regensburg. Not least because transfer can be carried out anywhere and the system offers all degrees of freedom – so that there are no limitations. The specialists at BMW have also come to appreciate the mobility of the measuring system. The Track ScanArm also plays a similarly important role for the Regensburg plant as a replacement for and a supplement to the underfloor measuring system, in order to avoid capacity bottlenecks. If the stationary measuring machine is busy, the FARO system offers the flexibility of enabling positioning the vehicle wherever there happens to be space at the moment, and the measurements can then be carried out there. In cases where the item to be inspected can only be transported into the measuring area with great difficulty, if at all, the Track ScanArm also offers the possibility of going straight to the part, for example to the production line, in order to carry out the measurements in situ. Thanks to the portability of the system, the specialists in Geometric Integration can make considerable savings in terms of transport costs and time. And when in this context the analysis is carried out more quickly, it is of course also possible to respond more quickly to any inaccuracies, which represents a significant advantage particularly in the series production process. One essential bonus of this system is the option of using each of the products individuthese measurements, the system is particularly impressive not only for its mobility but also for perfect ‘job-sharing’: The measuring arm is used whenever measurements need to be taken in locations that cannot be accessed by the laser tracker.

The tracker is used, on the other hand, for measuring points at heights of up 3.0m which cannot be reached with the measuring arm. The combination of tracker, tactile measuring arm and laser scanner has proven absolute stood the testing in both Dingolfing and in Regensburg. Not least because transfer can be carried out anywhere and the system offers all degrees of freedom – so that there are no limitations. The specialists at BMW have also come to appreciate the mobility of the measuring system.

The Track ScanArm adds another element to the existing comprehensive array of measuring devices in Dingolfing und Regensburg, and quite considerably increases efficiency in the case of certain measuring tasks. On this basis, the metrologists can select and utilise the most effective measuring system available in each case, for any application. This also applies especially with regard to the combination of scanning and tactile measurement for large measurement volumes, and the possibility of mobile deployment on the production line.

measuring assembly jigs.

Roland Schlüßl, Key Account Manager at FARO and responsible for BMW client support, sums it up as follows: “The experts in Geometric Integration measuring technology at BMW are quite satisfied with the Track ScanArm system. And it’s no wonder, as the automotive industry is virtually predestined for the combination of these measuring systems, because the components to be measured are too large for the measuring arm, and the laser tracker can do little on its own. Admittedly, we also learned quite a lot in the course of the installation process at BMW, and we were able to develop the Track ScanArm even further in the process. Now the package is absolutely ‘spot on’ and is already being used by various other car manufacturers.”

5 Good Reasons

… why you should consider the FARO Track ScanArm:

Combination of FaroArm and tracker: Large range, small details which are difficult to access, highest precision

Benefit from the high accuracy of both individual systems

While measuring with the arm it is not necessary to be in line of sight with the tracker. Thus you measure/ scan with real 6/7 free axes

Only one laptop necessary for the control of both products

Laser Tracker and ScanArm can also be used indivuaally