Create complete mine projections and ventilations in minutes vs. hours with all the tools needed for precise design and scheduling

The Carlson Underground Mining module enables users to individualize their design with:

- Choice of pillar designation and preferred method of locating pillars and rib lines

- Ability to choose ventilation directions including automatically placing stops, man-doors and escape ways

- Option to enter mine survey notes by azimuth or in a spreadsheet-type dialog

- Use of full array of mine symbols from the Mine Symbol Library or ability to define your own to create the final map

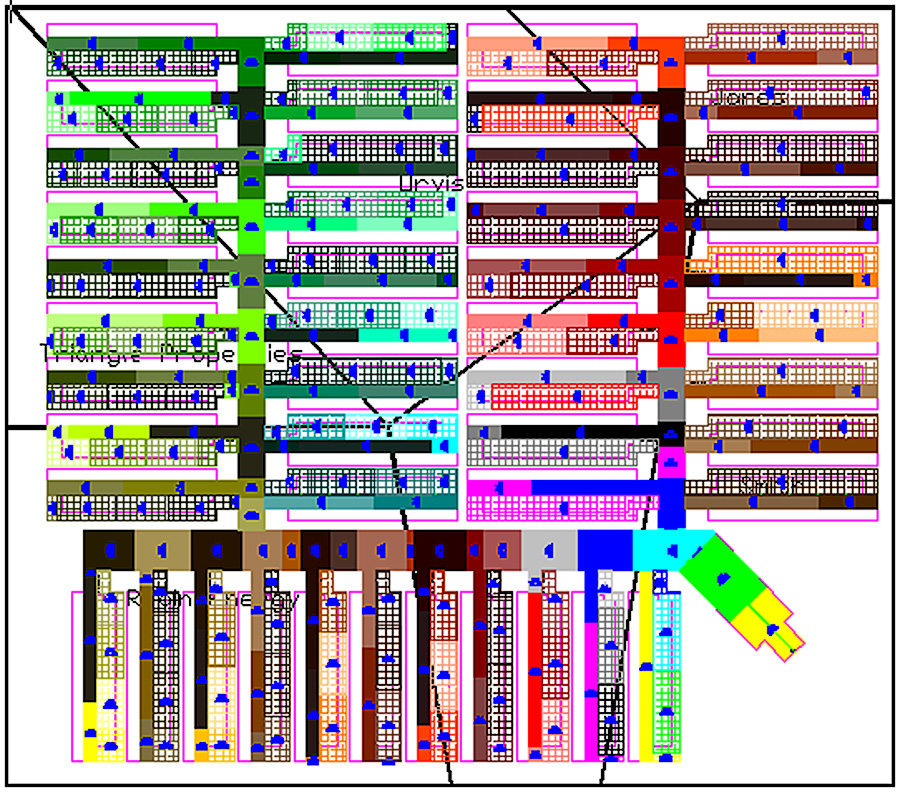

Timing is everything. Carlson’s timing routines provide valuable information to help assign equipment to reduce idle time and increase production rates by avoiding illogical, delaying layout elements and precedence. Retreat mining may be part of the schedule, splitting the panels by advance and retreat. Added options for color settings for enhanced visual feedback in the underground timing sequencing. Retreat mining can also be included in the scheduling, splitting the panels by advance and retreat.

All of this is accomplished with Carlson Software’s renowned ease-of-use, thereby increasing efficiency and savings.

Underground Mine Mapping

- Process survey data and generate the mine map seamlessly with the mine mapping features in Carlson’s Basic Mining or Underground Mine Modules

- Calculate end-of-month tonnage on each section in one of three ways with Quantities, either by: Average, Grid, or Centerline

- Use the full array of mining symbols from the Mine Symbol Library, or build your own library of mining symbols, pillaring

Longwall Mining

plans, point symbols, or map symbols

- Automatically connect the survey data using Auto-Connect Pillars

- Layout your room and pillar mine automatically using Advanced Panel Layout features

- Draw and then view the underground in 3D

Underground Mine Reserves

Determine these complete with quality attributes, thickness, and grades calculated and displayed using user-defined parameters, such as:

- Tonnage

- Overburden

- Area mined

- Qualities

- Periods

- Equipment

- Cost

Underground Scheduling

Get valuable information with Carlson’s timing routines to assign equipment to reduce idle time and increase production rates by avoiding delaying of illogical layout elements and precedence.

Use the options for color settings to enhance visual feedback in the underground timing sequenceing. Also have ability to include Retreat Mining in the scheduling and split the panels by advance and retreat.

- Schedule timing and quality forecast, tying into the geologic model

- Individually schedule mining sections based on both productivity and operating schedules

- Forecast difficult mining areas using Difficulty Factors in several different ways; for example: as a function of time, location, or thickness

- Place drawing events in the mine to accumulate specific tasks such as belt moves, belt heads, stopping points, longwall moves, etc.

- Update your mine and reforecast quickly using one of two methods

- All reports export directly to XML Reports, ASCII text files, and more

- Automatically calculate extraction ratios when pillars are drawn, or input the ratio using simple closed polylines on the PERIM layer representing the panel

- Input much of the panel data by just keying in text on specifically named layers, such as Difficulty, Extract, Ret_Extract, and more

- Accumulate timing results by property owners