Ideal for quickly capturing highly accurate and detailed as-built conditions of historical structures and buildings, the FARO Laser Scanner constructs 360-degree point clouds of scanned surfaces to create 3D models used in building restoration or historic preservation plans.

Providing researchers and scientists with 3D CAD models of as-built plans used to determine structural integrity, the FARO Laser Scanner offers a robust solution for restoration or scientific analysis purposes.

Exploring inside a mummy

3D DOCUMENTATION: Museum visitors in Stockholm will soon be able to explore a real Egyptian mummy in a virtual autopsy that combines three scanning technologies for a ground-breaking new level of realism.

Since archaeologists first dared to enter the pyramids, the public have been fascinated by the exploration of relics from ancient Egypt. Now visitors to the Museum of Mediterranean and Near Eastern Antiquities – Medelhavsmuseet in Stockholm will be able to virtually peel away the layers and actually look inside real mummies that have been carefully guarded for more than 4’000 years.

The experience will be powered by Inside Explorer, a tool developed by Interactive Institute Swedish ICT. Thomas Rydell, Studio Director at Interactive Institute, heads the team of visualisation and interaction software specialists behind the project. He says “The ‘Inside Explorer’ system is already in use in a number of museums, but the textural detail of the mummy exhibit due to open in early 2014 is unprecedented.”

The mummy was taken to a hospital for a Computer Tomography (CT) scan, which provided volumetric information of the inside of the mummy. But CT scans do not provide sufficient surface detail. This is where FARO stepped in to help.

A FARO Edge ScanArm was used for the 3-day mummy scanning session, which was conducted by members of the Interactive Institute team and Autodesk: “We are software engineers and not measuring experts but we were able to use the FARO hardware almost immediately,” says Rydell. “FARO came in to help us get started and to check a few things that we might have otherwise missed.” The members of the team were swapping roles all the time and taking photogrammetric images, “so the ease of use and mobility of the FARO device was a huge enabler,” explains Rydell.

Now, with the mummies safely locked away to protect them from UV or physical damage, post processing is underway. Autodesk reality computing software is being used to create detailed textured meshes from the regular 2D photos and the cloud-point data.

The volumetric data from CT scanning and the textured mesh data from the surface scanning will then be combined in Inside Explorer, Interactive Institute’s own real time rendering software, creating an accurate digital representation of the mummy. Museum researchers or visitors will then be able to use simple gestures to explore the mummy as a whole, zoom in to see fine detail or go below the surface. “Thanks to the 3D scans of the surface, we have the possibility to get enough surface resolution to establish a powerful and realistic first impression,” says Rydell.

Users can also remove the sarcophagus, peel away the layers and explore the inside of the exhibit.

“We are software engineers and not measuring experts but we were able to use the FARO hardware almost immediately.”

THOMAS RYDELL, DIRECTOR OF INTERACTIVE INSTITUTE C-STUDIO

“You see the tissue and the skeleton – things which doctors and researchers have been able to look at for a long time – but this project brings it all together for the general public.”

As other museums begin to develop their own 3D-interactive exhibitions, FARO will be supporting the trend with easy to use, fast and flexible tools.

INTERACTIVE INSTITUTE SWEDISH ICT

Interactive Institute Swedish ICT is an experimental IT & design applied research institute dedicated to the creation of ground-breaking user experiences. A staff of 60 aims to develop expertise in interaction design, visualization, user behaviour, sound design, games and entertainment.

The mummy project is a collaboration between Interactive Institute Swedish ICT, Norrköping Visualization Center C, Center For Medical Imaging and Visualization (CMIV), Medelhavsmuseet, Autodesk and FARO.

FOUR GOOD REASONS (Thomas Rydell, Director of Interactive Institute C-Studio)

1 Ease of use: Everyone on the team got involved hands-on in the scanning and we are not metrologists. So the fact that we got such good results proves how easy it is to use a FARO ScanArm.

2 Service support: In all my interactions with FARO I was impressed by their helpfulness and service commitment. It made this whole project possible, and straightforward.

3 Resolution: The interactive illusion comes to life because of the highly accurate surface information provided by the FARO Edge ScanArm.

4 Mobility: We had to take the mummy to a hospital in Stockholm for the CT scans but the FARO ScanArm can easily be transported and positioned where you need them.

Successful scanning of Diseworth Parish Church to build digital 3D models

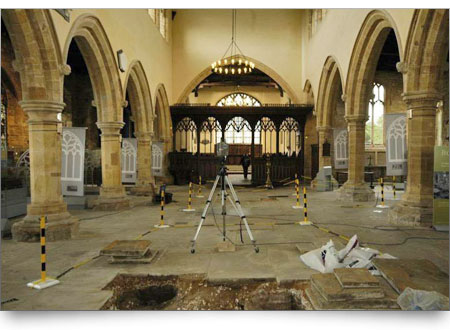

The Digital Building Heritage Group is a multi-disciplinary research cluster of staff and research students at De Montfort University specialising in scanning of historic buildings. The survey of this church is part of a current Arts & Humanities Research Council (AHRC) funded Connected Communities initiative in conjunction with the Trust’s ongoing All our Stories Heritage Lottery Funded (HLF) project called “A Thousands Years of History – Diseworth Parish Church from Mercia to Modern Times”.

St. Michael’s and All Angels was a prime candidate for laser scanning because of its complexity and delightful geometric “irregularities” which Successful scanning of Diseworth Parish Church to build digital 3D models arise from the many changes and additions that have been made to the building over its one thousand year history. Diseworth also has a superb little heritage centre in a recently restored Baptist Chapel. It was an ideal location for the field base for examination of the documentary evidence the Trust has collected about the history of their church and for discussing the detailed survey of the building fabric and the 3D modelling work. “This is a central part of the co-production process of this project, working together with the Trust volunteers and their experts not only to add value and a further dimension to their work but to enable them to adopt and use some of our digital technologies at a number of levels”, said Douglas Cawthorne.

The laser scanning process was started inside of the building and then moved to the exterior. “A major advantage of laser scanning is that you can accurately measure features dozens of meters away which makes measuring church spires and high vaults much easier and less risky,” added Douglas Cawthorne. “TheFARO Focus3D is particularly suited to capturing the complex forms of historic buildings at a level of detail that is particularly useful” highlights the leader of the Digital Building Heritage Group at De Montfort University. Before using the Laser Scanner time consuming traditional hand-survey measurements would have been needed but with the Faro Focus this time was cut substantially. To supplement the laser scans the Diseworth Heritage Trust had also undertaken a detailed photographic survey, focusing specifically on individual architectural features and materials. High quality photographs have for a long time been an important aspect of historic building documentation but photographs specifically of materials like wall surfaces and floors as well as of specific architectural features can also be used to produce digital “texture maps” which can then be applied to the 3D digital models to give them a realistic appearance.

“This is something we are keen to do with St. Michael’s and All Angels because the variation in materials, particularly in the stonework is important in communicating the developmental sequence of the building” highlights Dr. Cawthorne. The technology of modern laser scanning makes the process of acquiring dimensional data relatively straight-forward if planned properly. It’s the processing of that data and then using it to then build one or more 3D digital models of the building that takes time. The aim of using the 3D model is to show the building in a series of developmental phases from its earliest Saxon form in the early 11th century AD to its form as it is now. This is intended to assist the Diseworth Heritage Trust in explaining the history of St. Michael’s and All Angels through illustrations for a forthcoming book to be published by the Trust towards the end of the year.

Pushing the next generation of digitizing heritage

Relicarte have been working with museums in creating digital output for a varied range of outcomes, since 2006. Since then they have seen that the interest in digital content as a resource across the heritage market grow exponentially.

When Relicarte first operated in this sector, digitization in any form was largely unknown to anyone but the archaeologists who had recognized its potential as a tool for documentation and research, however the importance of creating digital content and its dissemination is now quickly becoming central to the industries future development. This is due to the ability of information rich digital content to be incorporated into Pushing the next generation of digitizing heritage both ‘on-site’ and ‘on-line’ supporting and supplementing heritage organisations collections and their targets in audience outreach and education. Relicarte have been in a strong position to observe the growing importance of digitized cultural items and continue to develop its services to deliver digital content of the highest standard and the platforms that allow the largest audience to interact with it in meaningful and exciting ways.

First steps into digitized scans

The first laser-scanning project was undertaken for the National Museum of Scotland, where a hired Konika-Minolta was used to digitize the iconic Lewis chessmen. These scans took an average of 6 hours of processing per chessmen to stitch together successfully back in those days, luckily things have moved on rather a lot since! The scans were then used to create a range of retail products through 3D printing, which was a largely unheard of process in 2006 and had to be done by a university. The retail products are a huge success and can still be bought from the museum to this day with no signs of their popularity waning.

The first purchased scanner of Relicarte was a first generation Next-Engine which served well but was of course very limited in the size of the object that could be digitized and still required a great deal of post processing to acquire a quality outcome. Due to the growing business of Relicarte they were looking for a new scanner which would allow to digitize larger subjects with increased accuracy and with less processing time and the search began. After kissing a few frogs Relicarte was introduced to the FARO range and in the end they purchased a Laser ScanArm Quantum with Geomagics package. This equipment package has vastly increased our scanning ability in terms of accuracy and quality as well as reducing greatly the turnaround time.

Earlier this year Relicarte also decided to buy a FARO Laser Scanner Focus3Das they move towards digitizing heritage sites as part of developing new services for the Museum and heritage industry.

Creation of “MY-MUSEUM”

“Relicarte has always been committed to innovation and during our involvement in this industry we have witnessed the growing importance of digital content as a public engagement tool alongside its roles in conservation and research” said Aegir Maciver, Owner and Director of Relicarte. Relicarte has identified the need for a single platform that both stores digital content and provides universal access to every form of digital output without complex specialist software.

Relicarte has created ‘My-museum’ as a complete solution for the production of digital projects from the generation of the digital content to its delivery as a public engagement tool. ‘My-museum’ delivers a fully interactive platform that provides online visitors with immersive access to cultural media, from fully rendered 3 dimensional arte-facts to fi lm, text, music and beyond. ‘My-museum’ is further designed as public engagement tool through which users can communicate with the Museum and their fellow visitors, generating a vibrant cultural conversation.

So far, Relicarte uses both Laser ScanArm Quantum and FARO Laser Scanner Focus3D to digitize divers heritage items for a public access project. “They are very reliable and predictable across a range of tasks” explained the owner of Relicarte. “Digitizing cultural items remains at the core of our companies work and in FARO we have what we believe to be the finest tools possible” emphasized Aegir Maciver, Owner and Director of Relicarte.

Ideal for quickly capturing highly accurate and detailed as-built conditions of historical structures and buildings, the FARO Laser Scanner constructs 360-degree point clouds of scanned surfaces to create 3D models used in building restoration or historic preservation plans.

Providing researchers and scientists with 3D CAD models of as-built plans used to determine structural integrity, the FARO Laser Scanner offers a robust solution for restoration or scientific analysis purposes.

Return to Industry Overview

Fascinating visitors in the Cathedral of Steam

3D virtual reality tours are a growing phenomenon, which allow the general public to experience the fascination of remote and inaccessible or delicate and dangerous locations. One such place is the D.F. Woudagemaal pumping station. Built in 1920 to drain floodwaters from the province of Friesland in low-lying Holland, it is the largest operational steam pumping station in the world with a mind-boggling capacity of one million litres per minute. Being a UNESCO world heritage site, the pumping station fondly called ‘the Cathedral of Steam’ has started a 3-year program of extensive renovations with engineering and consultant service provider Royal HaskoningDHV managing the work.

The first idea was to use 3D scans to create accurate ‘As-Built Documentation’ for the renovation work. But the project quickly developed to include solutions that also support the visitor centre during the long period of renovation. “We spent 10 working days collecting about 185 scans with a FARO Laser Scanner Focus3D. Together with some conventional surveying information these were registered in the software SCENE from FARO and then exported to the FARO WebShare environment,” explains Eric Borst of Royal HaskoningDHV. Web- Share allows any authorized user to log in to the server and explore the processed scans of the whole site. “So you can navigate around the pumping station and look at the full 360° colour views from each scan position. Then there are various user tools for in-depth examinations.”

“With more than 10,000 visitors per year and the building covered in scaffolding or with whole areas closed-off due to the renovation work, it was important to have an exciting exhibit in the visitor centre. We also wanted to maintain the interest of

more casual visitors.” So the next step was to export the data to Autodesk 3D Studio Max, with the Alice Labs Point Cloud plugin. This was used to create a virtual tour – a 6 minute film that visitors can watch on 32-inch touch screens. It is a virtual

flight through the building, with the option to stop in different places and see detailed information about the actual progress of the renovation work.” Borst and his team have also been able to take the visitors into places that you could otherwise never enter – like inside a steam boiler or down into the pitch dark areas below the waterline. “Because the Focus3D is so compact and light, we often acquire unusual perspectives. Dispensing with the tripod, we can stick the scanner down a drain or into a boiler casing – obviously something you could not do if the scanner was bigger or heavier,” notes Borst with satisfaction.

The cave paintings of Laas Geel

Thousands of years ago, our ancestors from the Neolithic age, decorated the walls of rock shelters at a place called Laas Geel with paintings of animals and humans. Little did they know that their work would last for perhaps 5,000 years and one day attract the attention of a team of Frenchmen armed to the teeth with 21st century advanced measuring technology. Discovered in 2002 by Professor Xavier Gutherz, from Paul Valery University (in Montpellier, France), Laas Geel is probably the most significant Neolithic rock-painting site in the Eastern part of Africa. But it is located in Somaliland, an autonomous region of war-torn Somalia – not the kind of place that you can easily investigate as an archaeologist or visit as a tourist. That is why the decision was made to create an accurate 3D model of the now endangered archaeological treasure. Having complete 3D measurements of the site will contribute to heritage preservation efforts, facilitate archaeological studies and allow the creation of immersive virtual tourism applications.

In April 2012, a team of five undertook the long journey from Paris to Laas Geel in the Horn of Africa to capture the necessary data. The expedition, manned by 3 archaeologists from the Paul Valery University and 2 scanning experts from the company Art Graphique et Patrimoine (AGP), scanned all 24 rock shelters and the cave paintings they contain. They also captured the site topography with a Total Station and made sub-millimetre level scans of the pre-eminent rock paintings. The French firm AGP has been a keen user of FARO scanners for over six years and are experts in immersive virtual reality for heritage preservation and promotion. “We use 2 FARO Laser Scanner Focus3D on a daily basis,” explains Didier Happe, CEO of AGP. “The Focus3D was perfect for the Laas Geel expedition because it is so light and portable, works on batteries for up to 6 hours and scans very fast. We also shot 36 mega-pixel images using a highresolution digital camera.”

“What you can do with the data really dependson how objectively you can integrate data from different scan positions and sources into a single database.

So we developed a rigorous method using targets and reference spheres as well as chromatic cards for colometric calibration,” explains Happe. “We also had laptops equipped with point cloud and 3D modelling software so we could validate and begin processing all the data. That involved some night shifts but we wanted to make sure we had everything before flying home.” “We are heavy FARO users so we are very grateful for the close support of the FARO team in France. They have always been a great help and the R&D department is always very interested in customer feedback,” says Happe with enthusiasm.

The FARO Focus3D scanner digitally maps the Cloaca Maxima beneath the Roman Forum

The laser scan provided the most precise information that can be obtained about the ruins, thereby adding to the knowledge acquired through studies conducted by the architect Giacomo Boni in the late 19th century.

THE MOST CUTTING-EDGE TECHNOLOGY FOR ONE OF THE OLDEST SEWAGE SYSTEMS IN THE WORLD

The FARO Focus3D scanner and its cutting-edge technology have helped Indissoluble (www.Indissoluble.com), a company specialising in multimedia architecture, to devise a successful solution to the digital mapping of the Cloaca Maxima, the sewage system beneath the Roman Forum.

No research had been conducted since the late 19th century, when for the first time in centuries the architect Giacomo Boni excavated Cloaca Maxima, the Roman Forum’s sewage system. Until now, his research represented the most detailed study of the archaeological complex and its underground monument.

One hundred years later, Boni’s legacy has been recovered by Patrizia Fortini, the head archaeologist in a project that seeks to revitalise and publicise this historic Roman heritage. To achieve this, Fortini teamed up with the Barcelona-based company Indissoluble as a technical partner.

Following the pioneering steps taken by Boni, her work carefully documented the archaeological site with the help of the latest technological tools. At the time, the architect was the first person to take aerial photographs of the site from a hot air balloon. Now, laser scanning by the FARO Focus3D has provided the most precise information that can be obtained about the mapping of the ruins, thereby increasing the knowledge accumulated through Boni’s studies.

Juan Roberto Vásquez, CEO of Indissoluble, discusses this important project: “Indissoluble is a company that works with the communication of spaces. We look for new ways to create and present content in cultural and business environments. We incorporate technology into all of our proposals and seek to innovate in the use of materials, construction techniques and interactive systems. Over the past year, Indissoluble has become involved in the preservation and promotion of historical heritage as well as the digital mapping of the Cloaca Maxima. We used the Focus3D to document structural conditions, produce new technical and scientific data and gather images for subsequent distribution. This activity is part of a project to revitalise historical knowledge about the Roman Forum, for which we have completed additional projects.

OVERCOMING HOSTILE ENVIRONMENTS AND DOCUMENTING COMPLICATED SPACES

Environmental conditions of the space being documented represented the biggest challenge to overcome in digitising the Cloaca Maxima. The work was carried out in complete darkness, in irregular underground conduits, with little room for movement and with additional complications due to the presence of water and waste. “We tried to come up with a technological solution that would allow us to overcome these obstacles in order to gain precise knowledge of a space that had remained unknown until now”, Vásquez adds.

One of the objectives of the new study is to document the condition of the Cloaca Maxima from three perspectives. The first relates to technical aspects of the structure, which will soon be closed due to the risk of collapse. Second, there is a scientific interest in verifying old documents and facilitating new archaeological discoveries. Finally, there is a public purpose, as the information gathered will form the basis of new publications and exhibitions for disseminating knowledge about Ancient Rome.

In this respect, the CEO of Indissoluble states that “The environmental conditions were the biggest factor in selecting which technology to use. We felt that it would be practically impossible to obtain the needed documentation with conventional tools and therefore selected the FARO laser scanner. The lightness and minimal size of the Focus3D allowed us to work in tight, irregular spaces and to carry the equipment comfortably along the 400-metre length of the sewage system. As such, we achieved the desired results.”

Specifically, Indissoluble used a Focus3D laser scanner to perform the digital mapping process, with which they obtained three-dimensional models of the main underground conduits and their relationship to the surface. Working inside the narrow and partially flooded conduits of the Roman sewage system, the scanning process was carried out in complete darkness.

ABSOLUTE PRECISION, TIME SAVINGS AND COST REDUCTION

The Focus3D helped to obtain three-dimensional models and geo-referenced sections of the main conduits of the Cloaca and the exterior. The mapping made it possible — for the first time — to establish the relationship between the monuments on the surface and the underground structure, as well as to establish the parameters for creating updated plans of the entire site.

One of the benefits was that by comparing the scans with the plans and old photos it was possible to appreciate the changes that had occurred there over the past few decades, mainly due to the accumulation of waste. The digital documentation also confirms the astonishing degree of precision of the 19th century plans, hand drawn by Giacomo Boni.

In addition to laser scanning, Indissoluble designed and built a remote-control-guided robot to explore the smaller conduits inaccessible to humans. The first version of the Archeorobot was equipped with cameras and sensors to gather environmental and location data. The project was carried out jointly with the Soprintendenza Speciale per i Beni Archeologici di Roma and Sotteranei di Roma and was sponsored by National Geographic España.

“It is a tool with great potential for application in numerous fields”, says Indissoluble’s CEO about the Focus3D. “After this experience in the field of archaeology, we are considering incorporating laser scanning into other projects involving the communication of spaces. Various improvements were achieved, including a reduction of costs on the order of 40% to 50% relative to conventional tools, both in terms of money and time.”

Conserving artistic and historical heritage with the FARO Laser Scanner Focus3D

“At GIM GEOMATICS, we are committed not only to integrating the most advanced technologies, but also to evolving according to our own ideas, making our line of research and development a hallmark that has received national awards and been endorsed by the Ministry of Industry.”

With clear dedication to customer service and a distinct profile as an innovator, GIM GEOMATICS relies on cutting-edge technologies, such as those offered by FARO, to provide top-class solutions for their customers and any companies seeking effective and efficient solutions to their problems in new technologies.

The increasing relevance of conserving buildings and infrastructures in today’s society, particularly those with an artistic and historical heritage, has highlighted the need to calibrate effective methods of analysis, planning, and implementation of the measures taken to restore buildings and structures. Traditionally, it was very complicated to reliably determine the thickness of a vault, so an “ideal” value based on an average “thickness” was used in the representation.

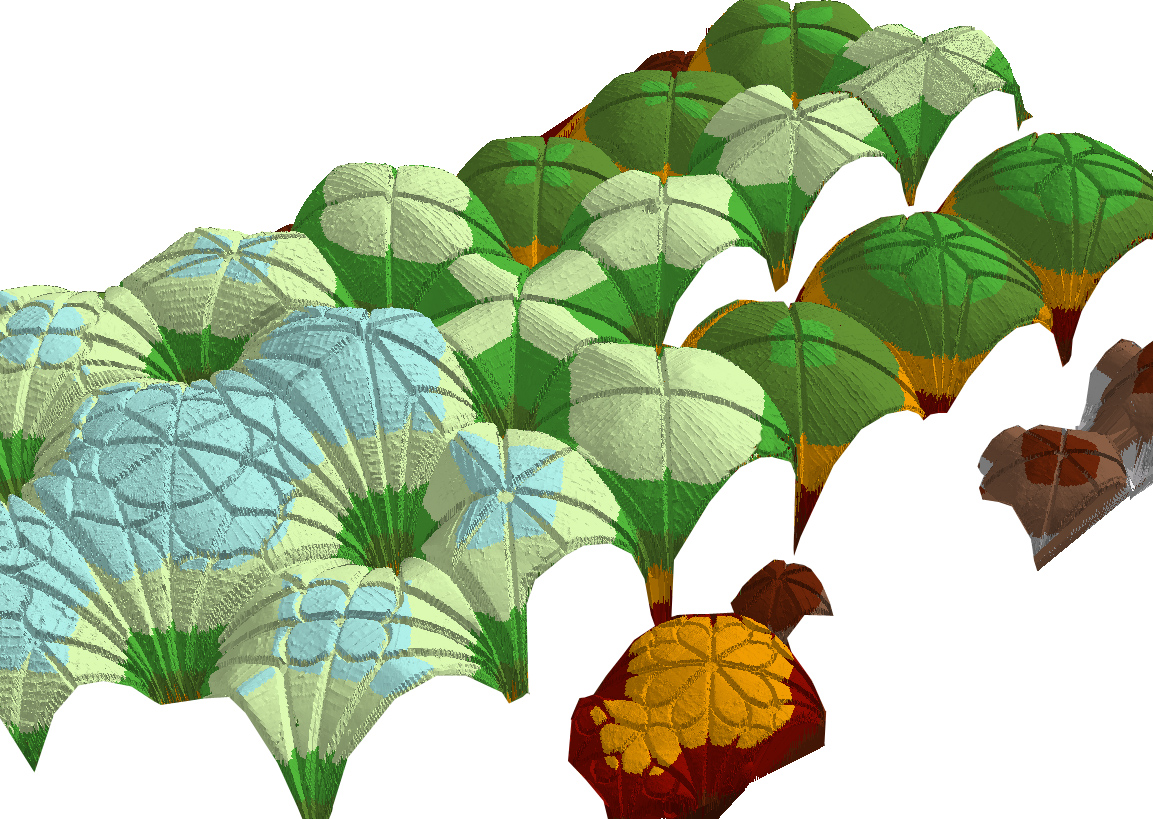

The cupola is a special architectural structure used to cover a space by means of profiled arches rotated around a central symmetrical point. Using the information captured using the FARO Focus3D and subsequent management of this data, it is possible to consider various solutions with different scales of complexity, ranging from traditional 2D results, such as contour line plans and continuous height plans, to the representation of information in 3D using nurbs, voxels and wire-frame models.

The quantity and precision of the available data permits real sections of the vaults to be traced, allowing their thickness to be seen. The FARO Focus3D is a product that has allowed GIM GEOMATICS to optimise their requirements, helping them to calculate a continuous model of vault thicknesses.

Scanning in 3D laser results in point clouds consisting of a set of vertices in a system of three-dimensional coordinates, normally defined using coordinates X, Y and Z. The superior quality of the raw data provided by the FARO Focus3D is the ideal starting point, and following detailed management of this data, they can be used to extract useful information in the form of elevations, sections, 3D models, orthoimages, visualisation applications, animation, and rendering.

In this case, even the real thicknesses of the vaults can be extracted, providing relevant information about the building as a whole, and about the different phases of its construction.

Using georeferenced point clouds obtained using the FARO Focus3D provides a highly-detailed and reliable solution to a complex problem which has traditionally created many headaches for geometers working in the heritage sector, providing objective criteria to assist in decision-making.

The result obtained was a continuous surface with vault thickness values every few mm2 or cm2 for the entire church. Based on this surface, and taking into account the materials, it is possible to estimate the vault passageway for structural calculations.

Benefits of using the Faro Focus3D

The revolutionary Focus3D laser scanner from FARO uses laser technology to generate three-dimensional images of geometries and complex environments in just a few minutes with an incredible level of detail. As it is so fast and reliable, the FARO Focus3D allows large volumes of data to be collected, which can then be managed in different project phases, without the need for any further data collection in the field. This enables the various solutions to be adapted to the specific requirements of each customer.

The benefits provided by the scanner mean up to 50% savings in the time required for scanning and processing in comparison with conventional laser scanners. This increases profitability for the product and contributes to a reduction in costs.

“We chose the FARO Focus3D because it creates a precise virtual copy of reality with millimetre-accuracy at an incredible speed of up to 976,000 measurement points per second. It also has a long range of up to 120m, a level sensor, a compact form-factor, ease-of-use and an auto-registration feature at no extra cost”.

3D documentation in the restoration of historic buildings

Coventry, April 2012. The church of St. Michael the Archangel (1735) stands in the centre of Borgo di Terzo, near Bergamo, Italy. Cracks were clearly visible in the front elevation masonry, indicating serious building damage. Due to its irregular architecture, the church – like all historic buildings – required a precise analysis of existing conditions as a basis for the renovation work.

Image: University of Bergamo, Faculty of Engineering

Exact measurements are enormously important, especially with structural intervention, and they form the foundation for structural analysis using the finite element method (FEM). 3D laser scanning is superb for the accurate recording of existing conditions. Comprehensive spatial data that can be used for structural analysis with standard software solutions is quickly and easily available. At the same time, all data is available for CAD design of the restoration. Compared with classic measurement methods, laser scanning is more accurate and efficient. The equipment is easy to operate and enables 360° data capture. Laser scanning provides records in which every individual point shows the same accuracy in the spatial coordinate system. Thus, it is possible to use the generated cloud of individual points (point cloud) not only for the investigation of a building component – as would be the case in measurement with a total station – but also to automatically record structural deformations of additional building components at the same time.

As a basis for the forthcoming structural improvements to the church in Borgo di Terzo, the engineering faculty of Bergamo University made use of a FARO laser scanner and was able to record the interior of the building in a single day. A graphical approach was chosen to filter and interpolate the scanning data for the detailed investigations that followed before the renovation. This enabled use of normal architectural procedures for the building analysis: for example, systematic investigation of crack patterns in the masonry to display the damage in the orthogonal projection or a comparison of the actual geometry of a vault deformed under its own weight with its ideal geometry.

In order to be able to use the church scan data with FEM, the point cloud had to be converted from a continuous model to a numerical model. Subsequently, sections relevant to the damage investigation and orthogonal to each other could be selected. Here, element grids with a uniform spacing of 30 x 30 x 30 cm proved to be a good compromise in representing significant parts of the building structure.

In the course of 3D documentation with the FARO laser scanner, the cause of the observed damage became clear: The timber roof framework had settled as a result of earlier restoration. Both a tie anchor and upper spines resting on the vault were affected. This led to heavy deflection and severe damage to the underlying vault masonry. The current load distribution in the vault was evaluated and distribution following the planned restoration was checked, using FEM analysis. It showed that both the arched buttress supports and the corresponding anchors required renovation. In addition, the middle arch must be reinforced with a steel grid and lime mortar. The deformation of the vault under load also showed that a tie member of the vault spine had given way, suggesting replacement of this anchor. After these reinforcement measures were incorporated into the FEM model of existing conditions, a general improvement in the entire structural condition became apparent.

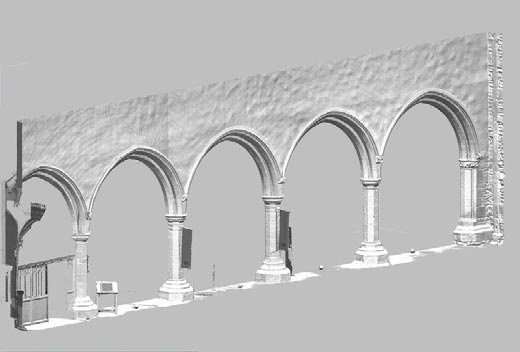

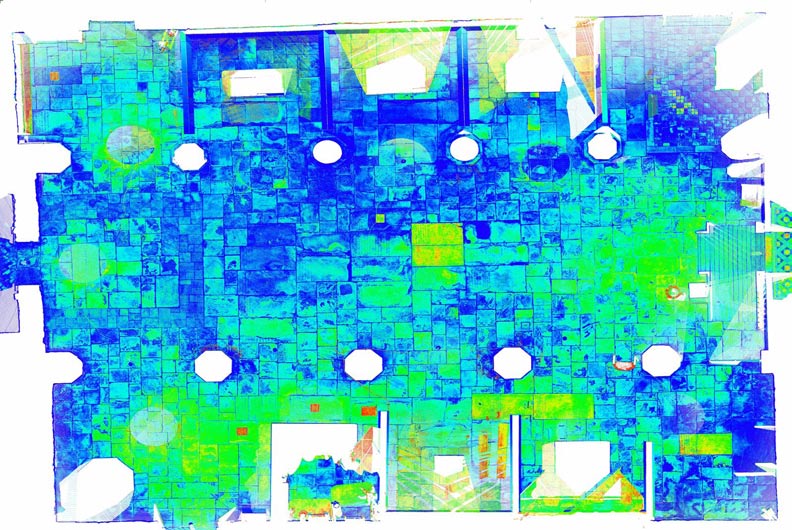

Scanning a 10th century church for English Heritage with the FARO Laser Scanner

English Heritage asked Geospatial Survey Solutions and Deri Jones & Associates (GSS/DJA) to provide a laser survey of St. Peters church, in Barton- upon-Humber, England. The requirement was a full laser scan survey of the interior of the site to produce a record of the floor heights for monitoring of subsidence, and to allow photographs of the 1980’s archaeological excavations to be used for photogrammetry. The initial survey was undertaken in August 2007 and they returned in 2008 to capture a further set of data to allow comparison and identify areas of subsidence. Saint Peter’s Church in Barton-upon-Humber can be dated back to the late tenth century and is among one of the most important historic buildings in Northern England. The structure combines an Anglo- Saxon tower and baptistery, with a high medieval nave and chancel all including a wide range of architectural styles. Saint Peter’s church is in the care of English Heritage who took over the building in 1978 and carried out a detailed excavation between 1978 and 1984. On both visits to St. Peters, a single day’s scanning was all that GSS/DJA required to compile the data they needed. As there was uncertainty on the long term stability of the building, survey references were placed outside the church on separate structures to minimise movement. These could also be used if an external survey was required in the future. The FARO Laser Scanner was used to capture the points, the separate scans were tied together using references gathered by their Total Station. The 2007 survey was used to create a detailed flagstone CAD drawing of the floor, elevations of the interior walls and reference data for the creation of photogrammetry models. Sections were taken through key points in the building to show the change in level of the floor along the length of the building. In 2008, the new survey data was aligned to the previous years data and a comparison drawing made of the relative levels, highlighting any subsidence. Height data for all of the 1600 flagstones in the main area of the church was processed, giving a very detailed survey of the relative movement of the floor over time.

About GS / DJA

DjA & GSS supply laser scanning, dimensional control, 3D CAD engineering and visualisation

services. Working with a variety of software packages, they provide the skills and experience to enable projects to go from 2D sketches to 3D components ready for manufacture and the ability

to capture existing structures for reverse engineering. As early investors in FARO’s large scale scanning equipment, GSS/DJA have gained a wide range of experience, from reverse engineering ship hulls to recording Roman sarcophagi. DJA/GSS’s team pride themselves on providing the highest accuracy of data and presenting the data in the most useful format to the client. With 15 years experience of 3D CAD and Digital content systems, DJA/GSS have the

ability to transform the massively detailed information recorded by laser scanning in to the correct end product for the client, whether it be IGES CAD surfaces, 2D CAD drawings or HDTV animated walkthroughs.

About FARO

FARO develops and markets computer-aided coordinate measurement systems and measurement software worldwide. The portable measurement equipment can be used for

production planning, and inventory documentation, as well as for the investigation

and reconstruction of accident sites and crime scenes. They are also used for digital scanning of historical sites.

4 good reasons

A portable non-contact measurement system using laser technology to accurately capture measurements. The system rotates 360° and automatically measures everything within the line of sight from the scanner´s position.

Optical Measurement: The intelligent laser system carries out optical non-tactile measurements.

Resolution: The scanner creates an image with an extremely high resolution of up to 711 mio. pixel per scan.

Measuring Volume: The laser scanner captures measurements within a spherical radius range of up to 76 metres.

Portability: With a weight of 14.5kg the laser scanner is easy to transport.