In thepast, machine shop inspection has required the removal of parts from a CNC machine to a temperature controlled inspection area for surface inspection or dimensional inspection of the part. This is time-consuming and expensive. Fortunately, incorporating portable CMMs from FARO directly into production lines can streamline this process.

The portability of FARO’s 3D metrology tools, like the measuring arm, enables efficient in-line, in-process and on-machine inspections. This delivers consistent, accurate measurements directly on or at the machine producing the parts.

Highest quality requirements in metalworking

METALWORKING / INSPECTION

The complexity of the metal parts produced, in terms of their geometry and the accuracy required has steadily increased in recent years. Expectations in terms of services have also increased, and the scope of measurement and test documentation plays an ever increasing role. Investment in the appropriate technology is therefore essential. The gap between the measurement effort and meaningful measurement results, which has become bigger in recent years, could not always be guaranteed with the previous measuring methods. The company KLB uses the Faro Fusion measuring arm to measure typical welded parts, punched and curved parts and for testing prototypes, among other things. The large amount of time needed for re-measuring various details of a component made the decision in favour of the 3D measuring system easier. For example, in the case of medium-sized welded parts (dimensions: L: 2133 mm; W: 940 mm; H: 1000 mm), with subsequent mechanical processing, hole patterns on all sides are checked with appropriate positioning tolerances. Thanks to the FARO Fusion the measuring effort has been reduced by up to 30-40 % compared to the conventional methods.

Measuring and analysis mistakes in high volumes of data have almost been eliminated thanks to the possibility of specifying tolerance ranges and subsequently analysing them automatically. Furthermore the measuring system is also used to record complex components for which there are no production documents available. In reverse engineering, for example, the documented measurement data are used as a basis for the design and production of construction plans. This is often particularly useful for old components, as in many cases there are no plans available for these. This means the replacement parts produced can be installed by customers without any problems, that is to say, without the additional effort of lengthy adaptations and checks.

The 3D measurement data also eliminate longlasting and possibly inaccurate manual measurement.

With the help of the CAM2 Measure 10 software from FARO, complete 3D documentation can be created, saving time and money in the quality department. Thanks to the software’s detailed measurement reports, the tolerances of various components can be quickly and clearly recorded.

The FaroArm Fusion also helps to reduce the measurement effort to the absolute minimum. Manfred Brüderle, quality manager at KLB Blech in Form GmbH, is convinced: “Our practical experience shows that we have generated considerable benefit and hence advantages in a variety of internal processes thanks to the use of FARO Fusion.”

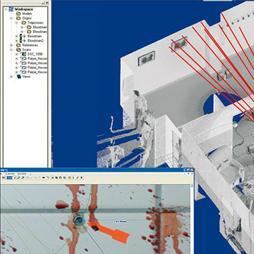

The FARO Edge checks the dimensions and geometry of special machines from NUMIREAL

A constructor of special machines and made-to-measure tools, Numireal checks the dimensions of its products with a FARO Edge measuring arm. This has enabled Numireal to become immediately operational, despite a lack of measuring experience.

Created in mid-2011 by its parent company, Cadbaz, Numireal manufactures a wide range of parts, tools and special machines, mostly individually, and with dimensions that range from a few dozen centimetres to several dozen metres (up to 48 metres to date…). The strategy adopted when it comes to checks is directly linked to that selected for production, as Thierry Docquier, manager of Numireal, explains: “By equipping ourselves with the latest generation of machine tools, we decided to focus on mastering the manufacturing process. We regularly check the settings of our machines, and this guarantees high production quality.” It is thus possible to considerably reduce or even eliminate checking of manufactured items. The focus then moves

to checking at the end of the manufacturing process; in other words, on the structures and machines assembled.

When it came to deciding on a checking method, those in charge at Numireal knew something about the direction to take because they had observed the methods implemented by subcontractors used previously by Cadbaz for the production

of equipment designed by its research department. “We didn’t hesitate. It was clear that the laser tracker and the measuring arm would best suit our requirements and our strategic choices when it came to checks,” says Xavier Muszak, head of production

at Numireal. For reasons of investment capacity, the company opted for a measuring arm. An initial analysis revealed several constructors offering an acceptable solution. “FARO was the most responsive and took a close interest in our needs.

Technicians from the company came to do a demonstration on our premises, in our industrial context,” explains Xavier Muszak, who appreciated this visit all the more since the company is not situated in a region specialising in mechanical manufacturing.

Moreover, the FARO measuring arm was a pledge for the future: “Eventually, to gain time and ensure more precision when it comes to checking lengthy structures, we will acquire a laser tracker; we have known from the start that this will be a FARO model, because it will use the same measurement software (CAM2 Measure) as the measuring arm. We will thus be able to capitalise on this software and preserve our investment,” continues Xavier Muszak. Events went on to confirm these careful preparations. FARO provided training on site, involving four people for two days. In addition to theoretical aspects, this training was targeted to the needs of Numireal, and practical work focused on concrete cases (in particular the adjustment of tools). This all adds to time saved later! Numireal was seduced by how simple the arm is to use. Numireal and Cadbaz have put in place a complete digital chain with no paper plans. The dimensions that need checking are defined directly using CAD models of the piece. The importing of the CAD models (realized using Catia) into the FARO measuring software poses no technical problems.

The Edge model used by Numireal from the FaroArm range covers a working volume of up to 2.7 m, with a repeatability of 0.064 mm. It is possible to extend the measuring volume thanks to the “leap frog” technique, which consists of moving the base of the arm along the piece, taking down reference points before and after each movement. “But you lose fractions of a millimetre

(several hundred) with each movement. And when you have to check a machine that measures a few dozen metres, this becomes important! It is here that the laser tracker comes into its own, and where the measuring arm complements the laser tracker perfectly. With the Edge arm and its seven axes, we can gain access to points that are difficult to access, which is impossible with a just a laser tracker, which digitalises what it sees,” concludes Xavier Muszak.

Geared up for success

SANDERS Gears Castings Machining prides itself in over 165 years of experience and is the expert in manufacturing non-standard gears, special castings and 5-axis machining of large and complex parts. Entirely in accordance with customer specifications: made to measure goods from a singular element to small series. SANDERS offers an excellent combination of top quality products and reasonable prices, with swift delivery. Founded by a blacksmith in 1846, it has grown to become a leading national and international supplier of quality services in the fields of gears, non-standard drive systems and specialty castings. They offer engineering and production of all types of gears, gear racks and gearboxes. SANDERS also has a foundry and complete machine shop for the production of machined castings like pump casings, impellers and gearboxes. They cast grey and ductile iron and special alloys like wear-resistant Nihard and tempered Ductile Iron suitable for thin-walled casting.

SANDERS’ heritage continues to be evident in the iron foundry and machine factory, but the company knows that the past means nothing if you don’t keep up with the future. That’s why they recently acquired a Faro Edge to support a broad range of activities across all the company’s departments.

“Our customers have one thing in common. They need repairs or replacements of gears, or other drive system components that are not available off-the-shelf. We are talking about straight, helical or spiral bevel gears and crown gears up to 5 meter and gear racks up to 15 meter” says Director Olivier Stapper. “Since we purchased the Edge we’ve been able to speed things up incredibly and we can handle large parts much better” says Stapper with enthusiasm. The Faro Edge also allows the SANDERS team to accurately measure large castings and casting patterns. When new parts are required for cranes, bridges or ships, on-site assessment and minimum down time are critical. Here the portability of the Edge gives SANDERS a major competitive advantage and is creating new business opportunities. “It allows us to measure complex shapes faster and more precisely, it’s easy to transport and it syncs with our CAM2 Measure software. Our engineering department has been using the FaroArm Quantum since 2009 and is very satisfied with its qualities. This made us purchase the new Faro Edge and again we experience time and cost-savings.” In the foundry and the machining shop, inline quality control is a major productivity booster breaking down the barriers between the traditional phases of manufacturing and quality control. Using the Edge, workers can easily measure complex products and react immediately to correct inaccuracies before final assembly. If any inaccuracies occur,

our personnel can respond directly and make corrections. As a result, we have less rejects and a higher quality product.

“A true innovation compared to the FARO Quantum is the built-in touchscreen and on-board operating system! We never know where we will use the Edge next; this can be everywhere in and around the work place, and at clients’ sites. The FARO Edge ScanArm also enables us to measure parts on location, which significantly saves time.” “The combination of our new FARO Edge and our traditional expertise in design and reverse engineering services is proving to be a great ROI booster for SANDERS and our customers alike,” concludes Director Stapper.

The certainty of “flying high”

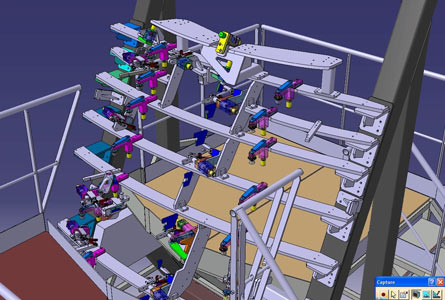

Mecat 5 is a small but active company based in the heart of Piedmont, which offers cutting-edge quality and technological contents in the special machine production sector, as well as mechanical processing for third parties. Isidoro Mirabella, the owner of the company, specifies: “We currently work mainly for large industrial groups, for example the Saet Group, the Tenova Group, Emco Mecof and Meccanica Nova, which, in turn, export their machines worldwide.” To work with such large and prestigious companies, it is necessary to produce high-tech products, observing the strictest precision parameters and respecting very narrow clearances.

Until just a few months ago, the Mecat 5 staff used an old-generation measuring tool with limits in terms of size, accuracy and data analysis. “To overcome these issues”, continues Mirabella, “and to be more competitive in one of the sectors that is potentially most interesting for us, and by that I mean aeronautics, we decided to invest in a modern instrument with advanced, start-of-the-art technology.”

In fact, Mecat 5 recently produced special equipment for REV Aviation S.p.A. – based in Chivasso, Torino – that Alenia uses to create nacelles for new Boeing 777 and 767 aeroplanes. “In addition to the production of parts, REV Aviation requires the respective dimension testing and inspection. Our need to use an adequate device derives from our client’s specific request.”

The instrument in question is a FARO Gage measuring arm, a portable coordinated measurement machine (CMM) with a work volume of 1.2 m, acquired by Mecat 5 at the start of 2012. Mirabella explains: “The FARO Gage is a portable 3D device with next-generation technology that can be brought to the worksite and can replace all other traditional manual measuring instruments thanks to the rich ‘library of instruments’ provided by the specific control software and report processing.”

Mirabella illustrates the results already obtained and the next goals for the use of the FARO device: “We can take advantage of the measuring arm’s full potential with the second series of aeronautical details to inspect. In any case, the FARO Gage has already shown that it can be particularly effective, with much better services than traditional instruments.”

The instruments allow measurements to be taken with a repeatability error of 0.018 mm in reference to the maximum width of the probe. Its wide range of probes and temperature and overload sensors also allow thermal changes to be “felt” and reaction to the improper use of the instrument thanks to its excellent precision.

Two of the most important advantages are flexibility and transportability. Isidoro Mirabella confirms and concludes: “The Gage allows us to easily perform direct measurements ‘on the part’ before taking it off the machine tool, reducing impact and defining ‘safe and repeatable’ processes from the point of view of size and precision.”

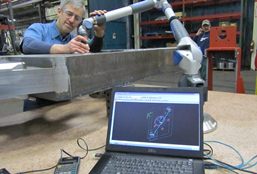

Brilex Improves Quality Program with FARO’s “Game Changing Technology”

Metal Fabrication / Inspection – Alignment & Verification

Brilex Industries has established itself as a worldwide source for fabricating, machining, and complete machine assembly. Founded in 1996 by two brothers, Brian and Alex Benyo, Brilex has become known as one of Youngstown, Ohio’s most aggressive and fastest growing companies. The company has grown to a position of leadership in its industry through proven performance, dedication, and continual investment in its people, facilities, and advanced equipment – providing both themselves and their customers with the advantages needed to compete in today’s global market.

With an aggressive and knowledgeable management staff focused on quality, efficiency, and on-time reliability, Brilex Industries (www.brilex.com) has become a preferred full service supplier to many leading OEMs and end users in the metals, rubber, plastics and glass, energy and power generation, and other capital equipment industries.

Problem

Problem

As expected for a manufacturer that supplies such a large range of industries and customers, the parts that Brilex works with everyday have an equally large range of size. Parts can range anywhere from as “small” as 30 pounds up to 70 tons. These parts tend to be medium to large fabricated and machined and/or assembled products such as various housings, gearboxes, platens, bearing races, scissor lifts, shredders, transfer cars, pressure vessels, chocks, bushings, work roll shafts, turbine components, and more.

Traditionally, Brilex used an assortment of tools in order to measure these various parts as it would be difficult for one tool to be the answer for all of their needs. They used OD (outside diameter) and ID (inside diameter) micrometers, height gauges, bore gauges, calipers, and other similar hand tools.

For Brilex, like many manufacturers, time and capability are always an issue. Over the past few years, the products the company builds and works with have become increasingly large and complex. In addition, many customers now require extensive documentation packages with complete traceability of material and dimensional resugalts.

The measurements obtained from traditional tools were sufficient, but were time consuming considering the increasing complexity of the parts and required multiple setups to measure all of the critical dimensions – if not impossible.

Solution

Brilex needed a better solution, a solution that could answer both their expanding need for quality and their ever-present need for time. Their answer came from FARO. The portable CMMs provided by FARO enable Brilex to perform many of the inspections they require with much greater accuracy and repeatability in a fraction of the time. Where it was not always possible to get all of the measurements they needed using past methods, they can now be achieved using FARO.

Brilex chose FARO not only for the time savings and the improved accuracy their devices provide, but for FARO’s industry reputation. The FARO equipment has even generated a great deal of excitement in Brilex’s customers when they visit and see them in action.

There was a learning curve in implementation of the new technology, especially in changing the mindset of those accustomed to using conventional measurement tools, but the combined training and support provided by FARO made this fairly seamless. That support was provided by local Account Managers Trevor Murcko and Eric Boyer as well as Applications Engineers and online support. Their assistance helped to show the benefits of reducing inspection time and proving the results that enabled Brilex to change their processes and improve their overall quality.

Brilex uses both the FaroArm and the FARO Laser Tracker ION on a daily basis to verify setup, in fabrication inspection, and during final inspection. A portable measurement arm, the FaroArm is used mostly on parts where GD&T is called out or in situations that may require additional setups. The FaroArm can be placed directly on the part or set on an inspection table and measuring can be started without having to setup or level the part being inspected. The scanning feature is used, for example, to check the profile of a casting and then compare it to the CAD file to assist manufacturing. The flexibility and portability provided by FARO are key and many of the software features in CAM2 are huge time savers for Brilex.

The parts checked by Brilex with the FARO Laser Tracker are generally those that are in excess of 20-ft long. Such parts typically require specific flatness tolerances. In other cases, such parts will have faces to be machined and the Tracker is used to verify that proper stock allowances exist. In some cases, subject parts have specific angles that are required to be held or machined. Another advantage of the Tracker is that it is very accurate in verifying specific locations over a long distance that must be held. Regardless of the length of the part, the Laser Tracker can be used to verify all features either in a single setup, or in multiple setups.

If multiple setups are required, reference points can be established during the first setup, then the Tracker is then moved to a new location and the reference points are picked up from the first setup and used for another set of measurements.

The FARO ION allows Brilex to check dimensions over greater distance and to inspect geometric fit, form, and function items that would otherwise be extremely difficult and cumbersome to evaluate.

Bud Geddes, Manager of Manufacturing at Brilex, said, “The most significant advantage of a laser tracker versus a conventional laser measurement system is the ability to establish datum points on the work piece being evaluated and leapfrog the tracker around the work piece. Doing this allows the user to measure relationships between features that would otherwise not be possible.”

“Some of the products we manufacture are fairly large and expensive,” said Dan Hall, the Quality Control Manager at Brilex. “When mistakes cannot afford to be made, we have used FARO, specifically the Laser Tracker ION, to ensure machine tool and part alignment prior to machining critical features.”

Return on Investment

For Brilex, their FARO solutions have improved their capability and confidence as well as the quality they deliver to their customers. FARO provides Brilex consistency in their results from inspection and this, in turn, allows the company to continually improve their quality program.

Alex Benyo, VP of Brilex, added, “The addition of FARO equipment is just another example of how Brilex continually makes investments in technology and resources to be best in class.” As an example of real return, a part that had previously taken an average of 5 hours to inspect, can now be inspected in less than 2 hours using FARO due to the time saved not having to retrieve and calibrate or to do additional setups with all of the other measuring equipment they used previously. Most of the products Brilex manufactures are not repeat production, but when they do work with more than one part, the time saved using FARO is also reduced.

“Having FARO instills a sense of confidence in our customer,” said Mr. Hall. “Having the ability to assure dimensional conformance of large products with stringent quality requirement has definitely played a role in the placement of several new orders. But, the greatest benefits we have realized are the time savings and the improvement in our ability to measure large fabrications – and the added confidence of our customers.”

Brian Benyo, Brilex’s president, said, “The ability to measure complex geometry in a quick and accurate fashion, anywhere on the shop floor, makes this technology far superior to having a CMM. With FARO’s user-friendly technology we are able to validate results during the manufacturing process, make adjustments and know that dimensional part requirements are met on the machine tool or at the fitting table. Having this ability is a total game changer.”

About Brilex Industries

Brilex Industries has established itself as a worldwide source for fabricating, machining, and complete machine assembly. Founded in 1996 by two brothers, Brian and Alex Benyo, Brilex has become known as one of Youngstown, Ohio’s most aggressive and fastest growing companies. The company has grown to a position of leadership in its industry through proven performance, dedication, and continual investment in its people, facilities, and advanced equipment – providing both themselves and their customers with the advantages needed to compete in today’s global market.

With an aggressive and knowledgeable management staff focused on quality, efficiency, and on-time reliability, Brilex Industries has become a preferred full service supplier to many leading OE Ms and end users in the metals, rubber, plastics and glass, energy and power generation, and other capital equipment industries.

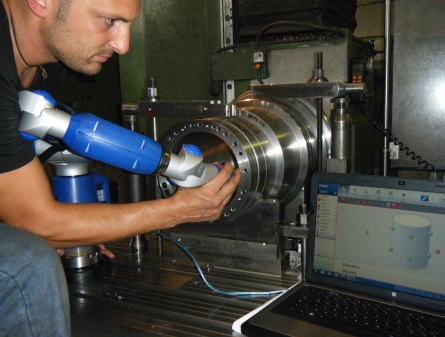

State-of-the-Art Measurements for Special Valves

The company’s Quality Manager, Giuseppe Ramponi, explained: “The particularity and geometric complexity of our products require highly specialized production processes and control procedures to ensure compliance with requirements and specifications.” To meet these requirements Petrolvalves has been using a FaroArm Platinum six-axis measurement arm with Measure X software (subsequently updated to CAM2 Measure 10) since 2005. “It is a sophisticated instrument that meets our needs perfectly,” Ramponi added.

Ramponi: “Tests demonstrated that this was the right instrument for our specific situation since it takes fast, precise measurements of geometrically complex components such as undersea actuators, worm-screws, special shafts and grooves.”

In short, the FARO Arm offers a level of precision that is comparable to fixed-coordinate measurement machines. In addition to taking up less space in the workshop, it performs inspections more efficiently and eliminates machine downtime.

In particular, FARO’s new Laser Line Probe gives the FARO Edge new functionality and performance with regard to contactless measurement that would be difficult to match. In fact, the wide laser beam significantly increases scanning capacity without sacrificing precision while ensuring extremely high speed and definition. Without forgetting that it is possible to optimize measurement and scanning operations with the CAM2 Measure 10 software.

Giuseppe Ramponi concluded: “We have only been using the new arm for a short time – it went into operation in January 2012, following the training course – however, we are already using it with excellent results. We have even begun measuring geometrically complex pieces and we are obtaining excellent results in terms of precision, reliability and speed.”

High Potential for Innovation

The FaroArm is able to convince users in everyday operation, thanks to its mobility and reliability.

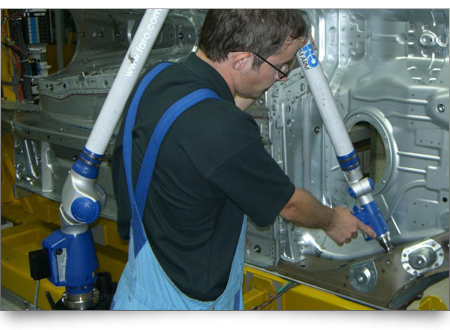

A portable FARO measuring arm has replaced conventional gauges for measuring bolts at a major automobile manufacturer. The FaroArm Platinum not only provides the premium manufacturer with considerable savings potentials from the standpoint of costs, but is also convincing due to its mobility and reliability in two-shift operation.

A large number of innovative technologies are deployed during the manufacturing process of the new BMW 7 Series in Dingolfing (Germany). Among them is a mobile measuring arm of the FaroArm Platinum series with a measuring range of 3.7m, which has been in use since the beginning of 2008 for measuring bolts that are distributed throughout the entire car for, among other things, attaching cable harnesses and brake lines.

Using the measuring arm also means that gauges are no longer needed. In addition, the new 7 Series is the first BMW vehicle in which the bolts are measured using the FaroArm. In addition to the Platinum series models, the FaroArm is also available as Fusion and Quantum model, as well as in five sizes with a spherical measuring range between 1.8 and 3.7 metres. Due to its capability to move in six or seven axes and its patented internal counterbalancing, the measurement system can also be used in difficult-to-reach places. The system’s measuring handle is equipped with four buttons that are used to control the arm; acoustic feedback provides the user with information on the status of the measurement.

The logic built into the arm uses rotary sensors in the joints to calculate the spatial position of the measuring probe. Overload sensors located in each joint warn the user when the arm is exposed to excessive handling forces, thus ensuring precise measurement results. The measuring arm consists of connection elements of a composite material developed by FARO – this not only permits a low weight (between 9 and 10 kg), but is also the basis for the excellent handling of the measuring system. In the course of production of the BMW 7 Series, random measurements of coarsethreaded bolts and earthing bolts are made on one vehicle per shift during the break, during which the system is at a standstill, so that production flow is not interrupted. The bolts are first measured in an inline measuring system by a robot with a laser sensor. In the next step, bolts that cannot be measured in this system because, for example, they are ‘hidden’ in the tunnel, are measured using the FaroArm.

To do this, the body shell is placed on a diverting frame and transported to a diversion and reworking workplace belonging to the floor assembly division in the production area. This is where the measurement technician first makes calibrations in the vehicle. Then he moves a sleeve over the bolt – and the measurement is already available. In other words, he did not have to touch the bolt. The approximately 60 bolts that are to be measured with the FaroArm Platinum are furthermore displayed by software that guides the user through the measurements. Compared to the previous method, this process also brings advantages in terms of time; as the gauges had to be inserted first.

The measurement technician moves a sleeve over the bolt, which means

that he does not have to touch it.

Since work in Dingolfing is carried out in two-shift operation, the FaroArm is deployed twice a day. However, in another application it is only used every two months. Because bolt measurement with the inline measuring system is referenced measurement, the Dingolfing plant needs a system for comparison. They also use the FaroArm for this. In this context, all the bolts in an entire vehicle are measured. Then the measurement experts examine how the data behave in relation to one another and the inline measuring system is calibrated on this basis.

The measuring arm replaces the measuring room in this case. In addition to advantages in terms of time, using the mobile measuring system gives automobile manufacturers the opportunity to replace their gauges. After all, they not only cost a large sum to purchase, but also require time-intensive tightening, including calibration in the measurement room, if the bolts are changed. In the case of the 50 to 60 gauges that the BMW plant has used for these measurements so far, this results in a considerable savings potential. In contrast to the measuring methods used before, the FaroArm also allows for the determination of precise positions, whereas the gauges only showed the deviations. The mobility and reliability of the FaroArm

Platinum also provide valuable benefits in the context of the resulting measurements. The measuring arm has certainly proven itself at the BMW plant, where eight other FaroArms are in use in other areas. It fully fulfills the task at hand, namely to use the portable measurement system to test whether the welded bolts are in the correct position. As the measurement experts are also very satisfied with the service, it can be concluded that the FaroArm has fulfilled expectations.

Moreover, the premium manufacturer has not only proven its spirit of innovation in the new BMW 7 Series – which is impressive due to its elegant design and state of the art technology – but also in the ‘refinement’ of the mobile measurement system: In order to measure the bolt more quickly, the BMW technicians have built an adapter that can be screwed onto the front of the FaroArm. The ball with which the measurements are usually made is removed. The sleeve is precisely one-tenth larger than the bolts. The engineer only has to place it over the bolt and check whether it rests satisfactorily on the plate – then he can carry out the measurements which only takes only about a second.

More information

WWW.BMW.COM

About FARO

FARO (NASDAQ: FARO) develops and markets computeraided coordinate measurement

devices and software. Portable equipment from FARO permits high-precision 3D measurements and comparisons of parts and compound structures ,within production and quality assurance processes. The devices are used for inspecting components and assemblies, production planning, and inventory documentation, as well as for investigation and reconstruction of accident sites or crime scenes. They are also employed to generate digital scans of historic sites. Worldwide, approximately 10,000 customers are operating more than 20,000 installations of FARO measurement systems. The company’s global headquarter is located in Lake Mary, Florida/USA, its European head office in Korntal-Münchingen near Stuttgart (Germany). FARO has branch offices in Brazil, Canada, China, France, India, Italy, Japan, Korea, the Netherlands, Poland, Spain, Switzerland, Turkey and the UK.

More information

FaroArm

The FaroArm product line consisting of Quantum, Platinum, and Fusion, are flexibly deployable, portable measuring systems for 3D measurements. They meet the high accuracy requirements posed by development and production. The FaroArm measures, digitizes, or creates a CAD component analysis right in production or during assembly. The measurement arms are available with six or seven axes and with four measuring volumes.

More information

http://europe.faro.com/products/metrology/measuring-arm-faroarm/overview

4 good reasons

The measuring arm can be mounted and operated very easily, regardless of the surface

being worked on.

Mobility: Large and heavy components must no longer be transported to the measuring machine. Quality control can be completed on-site with the measuring arm. A patented temperature compensator assures reliable measurement results.

Flexibility: Thanks to the use of multiple rotary axles, the measuring probe can be positioned at the point to be measured, even if it is difficult to reach.

3 Counterbalance: The internal weight counterbalance in the FaroArm enables measurements to be completed beneath its clamping frame and allows unencumbered work

Universal mounting: The measuring arm can be mounted and operated very easily, regardless of the surface being worked on.

How the FaroArm works:

In order to measure a specific point, the measuring probe is positioned at the spot to be measured. The rotary angle encoder located in the arm calculates the exact position of the probe.

Express Manufacturing Gains Full ROI with the FARO Gage

Express Manufacturing

did a trial program called the FARO Technology Test Drive (program valid for the American markets) which enabled them to evaluate the equipment in the “real world” situation of their own shop floor. With a minimal investment and no risk, they were able to test the Gage and prove out its ROI before purchase.

Express Manufacturing is a job shop that is dedicated to quickly producing accurate parts

for their customers. Based in Acton, Ontario,Express specializes in aluminum, mild steel, and even wood. With a goal of being an affordable machine shop, they focus on jobs with

smaller quantity outputs which best affords them the opportunity to do what they do best –

work quickly with accurate parts.

Problem

With a primary focus in the aerospace industry, specifically landing gear, Express Manufacturing

often must inspect bearing surfaces and mating surfaces with very tight tolerances. Solely using

micrometers and electronic height gauges on these parts created issues of time and material

waste and, generally, some frustration. Another issue that can also potentially hinder

achieving the desired high accuracy is the problem inherent with removing a part from a

tooling machine while in-process. Despite the best of efforts, it is difficult, if not impossible,

to set a part back into a machine for re-tooling exactly as it was before. In addition, simply

removing the part from a production machine for inspection and verification is, in itself, both

time consuming and expensive.

Solution

Inspecting parts directly on the machine >>producing them not only increases productivity, but also quality. On-machine inspection allows the machine tool operator to quickly and easily inspect parts directly on the floor while the part is being machined – resulting in tighter tolerances with fewer errors and re-work. Express Manufacturing was looking for a solution that would provide them the advantage of true onmachine inspection. That tool is the FARO GagePlus. The Gage is a highly accurate and easy-to-use measurement arm. It’s designed to be used directly on the shop floor and is ideal for on-machine inspection. Eric Wenger, the owner of Express Manufacturing, said, “On-machine inspection is where the FARO Gage shines and it really helps us a lot.”

They will still “double check” with the height gauge, but they can be confident in the part before

they take it off the machine. This saves them a lot of time, material, and that frustration.

Return on Investment

Express did a trial program called the FARO Technology Test Drive (program valid for the American markets) which enabled them to evaluate the equipment in the “real world” situation of their own shop floor. With a minimal investment and no risk, they were able to test the Gage and prove out its ROI before purchase. An added bonus for Express is now having a CMM

in their shop. They have since reverse engineered parts and have been able to verify the quality of parts they’ve been making for years. In fact, they verified their measurements using the FARO Gage with a very expensive table CMM and found no discrepancy at all.

“The implementation was very easy. Especially with the Test Drive program and training,” said Wenger.

“We have better piece of mind now.”

The Gage has improved Express’ process measuring time and the accuracy of parts before taking them off the machine – again, saving a lot in material cost.

“The Gage turned a five week job into a three week one,” said Wenger.

“We have saved about $15,000 so far in the year we’ve had the Gage and this figure would

be much higher if not for the rough economy. I project that FARO will save us about $25,000 to $30,000 a year in a normal economy.”

Wenger also said one unexpected benefit of having the FARO Gage is,“It’s a great selling feature for when people come to see the shop. Customers like the fact that it’s in the shop and we always make it visible when they come.”

About FARO

FARO develops and markets computer-aided coordinate measurement systems and measurement software worldwide. The portable measurement equipment from FARO permits high-precision 3D measurements and 3D comparisons of parts and complete systems within

production and quality assurance processes. They are used for inspecting components and component assemblies, production planning, and inventory documentation, as well as for the investigation and reconstruction of accident sites and crime scenes. They are also used for digital scanning of historical sites. Today, approximately 10 000 customers worldwide with more than 20 000 installations have put their trust in the company’s measurement systems (NASDAQ:FARO).

4 good reasons

Contact Measurement: Interchangeable ,probes mean the FARO Gage can be used to measure different geometries.

Ease of use: Universal hinges make it easy for the operator to move the Gage around all kinds of objects, minimising fatigue.

Volume of 1.2m: Small parts and moulds can be easily processed in the Gage’s 1.2m (4ft) measuring volume.

Portability: The Gage is a portable device for jobs needed on different areas of the shop floor.

Speed and flexibility gains in electrical motor production

The German industrial manufacturer Siemens is well equipped with a number of FARO arms to speed quality control and increase production flexibility in the Large Drives Business Unit.

The German-based industrial multinational Siemens needs no introduction as a global leader in drives, automation, transport, building technology, lighting and industrial solutions. Within the Drive Technologies Division, the Large Drives Business Unit makes motors and the associated transformers and control components that are found in railway locomotives. Further products include drive systems for machines used in the textile, packaging and printing industries.

The manufacturing quality control department of Siemens Large Drives Business Unit uses five FARO arms.

About 210 employees are involved in the unit’s mechanical manufacturing department on Vogelweiherstraße in Nuremberg. Supporting them is a team of 8 metrologists in the quality control / measuring department. In 2005, they acquired their first FaroArm Platinum, to replace a conventional 3D coordinate measuring system and a range of manual methods. Excited by the substantial timesavings, Siemens added another four FARO arms when the Quantum became available.

“We heard about FARO products at an exhibition and then attended an Open House event organized by FARO Europe. Having seen the equipment demonstrated we were no longer surprised by the astonishing time savings that we were able to achieve with FARO arms,” explained Karlheinz Leitner, Head of CNC Programming in the Mechanical Production department. “We estimate that we are now making time savings of 50 – 60% over our previous methods of measurement. Furthermore, using the FARO arms has many wider benefits.”

Parts are made in batches, and every time a new batch is started, the first part needs to be taken to the quality control department and approved before the rest of the batch can be completed. With a FaroArm, the time required for measuring is substantially reduced; so smaller batches have become more economical. This increases production flexibility. Parts can even be measured while still mounted in the manufacturing machine thanks to the portability of the FARO arms.

Normally parts to be measured range between 0.2 and 1.2m in size, but sometimes parts exceed the standard 2.4m volume of the FaroArm Quantum. However Leitner is unperturbed: “Using the leapfrog method with magnetic reference points, the range can be easily extended.”

The Siemens Large Drive Business Unit works with Delcam PowerINSPECT software, which integrates seamlessly with the FaroArm. When a new part is introduced, the quality team creates a measurement program based on the available 3D plans. This defines the required measurements and tolerances. Thereafter, the operator can simply take the measurements and automatically generate a report. “All in all, we are very pleased with the productivity increases that we could achieve thanks to the ease of use of the FARO arms.”

About Siemens AG:

Siemens AG is a global powerhouse in electronics and electrical engineering, operating in the industry, energy and healthcare sectors. For over 160 years, Siemens has stood for technological excellence, innovation, quality, reliability and internationality. In fiscal 2010, revenue totaled some €76 billion and net income €4.1 billion. At the end of September 2010, Siemens had around 405,000 employees worldwide.