Effective planning is critically important to architects, construction engineers and contractors in any type of construction project. 3D documentation at every stage, from initial design to final inspection, helps avoid costly rework errors.

Architectural practices, construction engineering companies and building contractors have all adopted FARO’s 3D laser scanners for 3D modeling andas-built documentation. Their projects range from simple house construction to inner city renovation and new office construction. From low to high rise, FARO has the right portable 3D solution for you.

With the FARO scanner, Escaliers Cochard has no more worries with staircase installations

Escaliers Cochard builds made-to-measure stairs, adapting them to the configuration of the site as closely as possible. This means it is always essential to visit the site in person, to survey the topography of the premises. The tiniest detail is important here! If the staircase is to be placed in the corner of a room, it is essential to take into account the angle of the walls and whether they slope or bulge out or in. It is also important to note the presence and location of any switches or electric sockets.

For a long time, Escaliers Cochard used traditional measurement methods, notably laser rangefinders, and trigonometry formulas to calculate angles. Things went fairly quickly when dealing with relatively new buildings, with flat, vertical walls forming right angles. “But a large number of the staircases that we install are located in old houses and buildings where the walls are distorted and often sloping. They may also have protuberances, such as beams sticking out.

All of this need to be taken into account, meaning that the survey could take a long time, sometimes several days,” explains Jean-Michel Cochard, founder and manager of Escaliers Cochard. When the client’s building is situated tens of kilometres away, the cost of the survey could become very high (in terms of travel and work time). “Since we started using FARO’s laser scanner, things have become much easier. Surveys are carried out in a few hours at the very most. We are also guaranteed not to forget anything; we no longer have to return to the site to check a particular detail. We bring the client’s home to us!” continues Jean-Michel Cochard.

The founder of Escaliers Cochard is passionate about technology and monitors technological developments constantly. He had therefore been aware of the existence of laser scanners for a long time (via the Internet) and knew that they could make his life easier. But the investment was not insignificant for an SME…

With the arrival of the new FARO model, which is less bulky and less expensive, Mr Cochard decided to take the plunge, telling himself that he could easily pool use of the instrument with another company if he had problems getting a return on his investment. After all, he felt it was a universal tool that could prove beneficial to all associated trades (architects, surveyors, decorators, builders, heating engineers, etc.). This idea quickly proved unnecessary, as the laser scanner was in use every day…

Beyond the functions themselves, Escaliers Cochard was delighted with the tool’s ease of use. After a few hours of onsite training provided by FARO, the company “took control” of the scanner and other people were trained on the job. Use of the scanner proved much easier than expected, remarks Jean-Marie Cochard: “FARO gave us recommendations to guarantee the tool’s precision. In fact, some of them were superfluous because its intrinsic performance largely goes beyond our needs and a slight decrease in precision is not a problem.” For instance, in a building where it is necessary to survey several rooms or levels, Escaliers Cochard does not deem it essential to apply the entire process of restarting the device, enabling time savings.

3D documentation of the magnificent glass roof of Leicester University Engineering Building

3D SurveyScan LLP acquired a Faro Focus3D in December 2011. They realised a potential in the market to offer a service using the scanner in various industry environments. 3D SurveyScan was amazed as to how little these industries knew of 3D scanning and point clouds. Even today, people from all industries are just beginning to realise the potential of using scanning to assist them in their day-to-day projects. Especially as BIM (Building information Modelling) is the way the government is pushing the industry forward with revit being the choice of software to model in. Before measurements would have been carried out by disto and tape measure. “The package 3D Surveyscan is offering is very flexible from providing a basic point cloud for the client to use themselves to model. Or we can give them the whole package including modelling services” states Ron Smith, co-owner of 3D SurveyScan LLP. So far 3D SurveyScan has produced quality packages for varying markets. Ranging from private dwellings, retail outlets providing floor and ceiling plans, to National Grid pumping stations, to office buildings including ceiling voids and heritage work.

Scanning of glazed roof area of Leicester University Engineering Building

The heritage work of 3D SurveyScan included a project to scan the Engineering Building at Leicester University with its magnificent roof made of glass. Built in the early 1960s it is due a major overhaul to replace the glazing in March of 2013. It was the task of 3D SurveyScan to produce a point cloud for the client to model the new roof using revit. “Because of the size of the roof we scanned the building completing 16 workspaces averaging between 30 and 40 scans per workspace” Ron Smith pointed out. The workspaces would involve both internal and external scans. All targets and deadlines were completed on time for the project. Scanning took place over a period of 10 days. Registration of the scans was achieved using the FARO Software Scene 5.0 in combination with the laser scanner. Preparation was really important and checkerboard targets were used as the main form of correspondence. Spheres were used to gain registration into smaller rooms. Because of the size of the project a total station was used in conjunction with the Faro Focus3D to produce control conditions for the project.

7 meter mast

Often 3D SurveyScan has to measure roof voids and they had height problems for the scanner. Now they have been overcome with a unique mast system reaching up to height of 7 meters. To start the scanner automatically 3D SurveyScan LLP has acquired a Samsung tablet which links in to the WLAN system on the scanner. Ron Smith also highlights “FARO Webshare is to be a very important part to our business. It is a major advantage to publish the scan data on FARO Webshare to enable the client to view and share the date. Clients are fascinated to see they can gain access to measurable information via our server at our office. This information is of course protected at source so only the client can gain access to their personal information”.

Laser scanning revolutionises architecture and the building industry

Coventry, February, 2013 – FARO Technologies, Inc. (NASDAQ: FARO): Detailed and reliable measurement data is particularly necessary in the measuring and planning phase of buildings and in building refurbishments – for both interior spaces and outdoor facilities. Because accuracy and error-free measuring are the basis for all sound planning and inventory surveys, the simple processing of 2D views is now no longer enough in most cases.

Examples from the architects at “laser scanning architecture” show how planning errors can be avoided and the efficiency of projects increased with the fully automatic Focus3D laser scanner from Faro. The office in Hannover was assigned the task of checking the existing drawings of an office building. These were to be compared with the as-built situation. Measurements of the shell of the administrative building to be renovated were taken with the FARO Focus3D laser scanner. Architect Johannes Rechenbach made 30 individual scans in just five hours, comprehensively documenting 2,800 square metres of façade surfaces and 1,500 square metres of floor space in 3D.

Architectural firms predominantly work in 2D these days. As a result, distortion-free 2D presentation is essential as a basis for planning buildings and interior spaces as well as outdoor facilities. Complete 2D images, such as floor plans, cross-sections and elevations, can be created from the three-dimensional scan data that is produced with the FARO Focus3D. These can then be imported, true to scale, into CAD programs. This makes it easy to compare the planning status with the existing building: possible planning errors are detected in good time and can be remedied before the construction phase. This avoids substantial liability risks and ensures that the major requirements with respect to accuracy and efficiency are calculable.

In the specific example of the aforementioned office building survey, significant differences are evident using the laser scanning method. In comparison with the existing CAD plan, clear discrepancies can be detected in the actual building in the region of the central supports and the right-hand exterior wall.

If such discrepancies are only noticed during future construction work, significant additional costs may be incurred and functional disadvantages in the design could arise. Instead the required planning certainty is achieved in good time using 3D measurements taken with the FARO laser scanner. The differences between existing and planned dimensions on all floors of this property amounted to approx. 30 square metres. A potential loss of rentable floor area was thus identified and communicated in good time. The accurate Focus3D measurement results were also to be used for the façade measurements. Following an analysis and direct comparison with individual manual measurements at sample points, it was found that the required accuracy of no more than 5 millimetres per window opening could not be reliably maintained with manual measurement. Discrepancies of between 0 millimetres and 15 millimetres were identified. However, the result could have been optimised still further by using tachometric calibration in parallel, but this would have involved a considerable amount of time.

The visual checking of axial grids, lintel heights and detail points was possible at an early stage of planning using overlaid scan data and the manually measured façade plans. This also represented a valuable aid in avoiding planning errors and ensuring a smooth construction process. The Focus3D measurements showed that the steel columns of the roof structure in this property (see image 2) are not centred over the masonry columns of the full floors. With this knowledge, the column cladding in the roof could now be positioned off-centre to achieve the desired uniform façade appearance.

The USP of 3D laser scanning with the Focus3D in comparison with other measurement methods lies in its ability to conduct integrated surveys of existing conditions and make multi-functional data analyses. Axonometric or perspective views from any standpoint can be generated from the scans. Video animations can be created with continually changeable camera tracks. The contents of the 3D scans also form a database for numerous innovative visualisation options.

As part of securing evidence, 3D scans with the FARO Focus3D serve to prove and portray the flatness of building components, for example. The areas shown in the picture in red are 2.5 centimetres in front of the reference plane. The areas coloured in blue are 2.5 centimetres behind it. This allows the state of the building to be accurately and incontestably documented, even after many years. 360° photographic-quality panoramas can be created with SCENE software, enabling visual and geometric analyses of the property. The quantity of data provided is so high that plans can also be prepared off-site. Visits to the building for follow-up measurements are rendered a thing of the past, saving time and money. As part of the bidding process, participating companies can view the high-resolution panoramas on the Internet, allowing them to submit accurately calculated bids. This also reduces construction costs. These panoramas can also be integrated into the architect’s or client’s home page.

Challenging assignment to save an architectural milestone

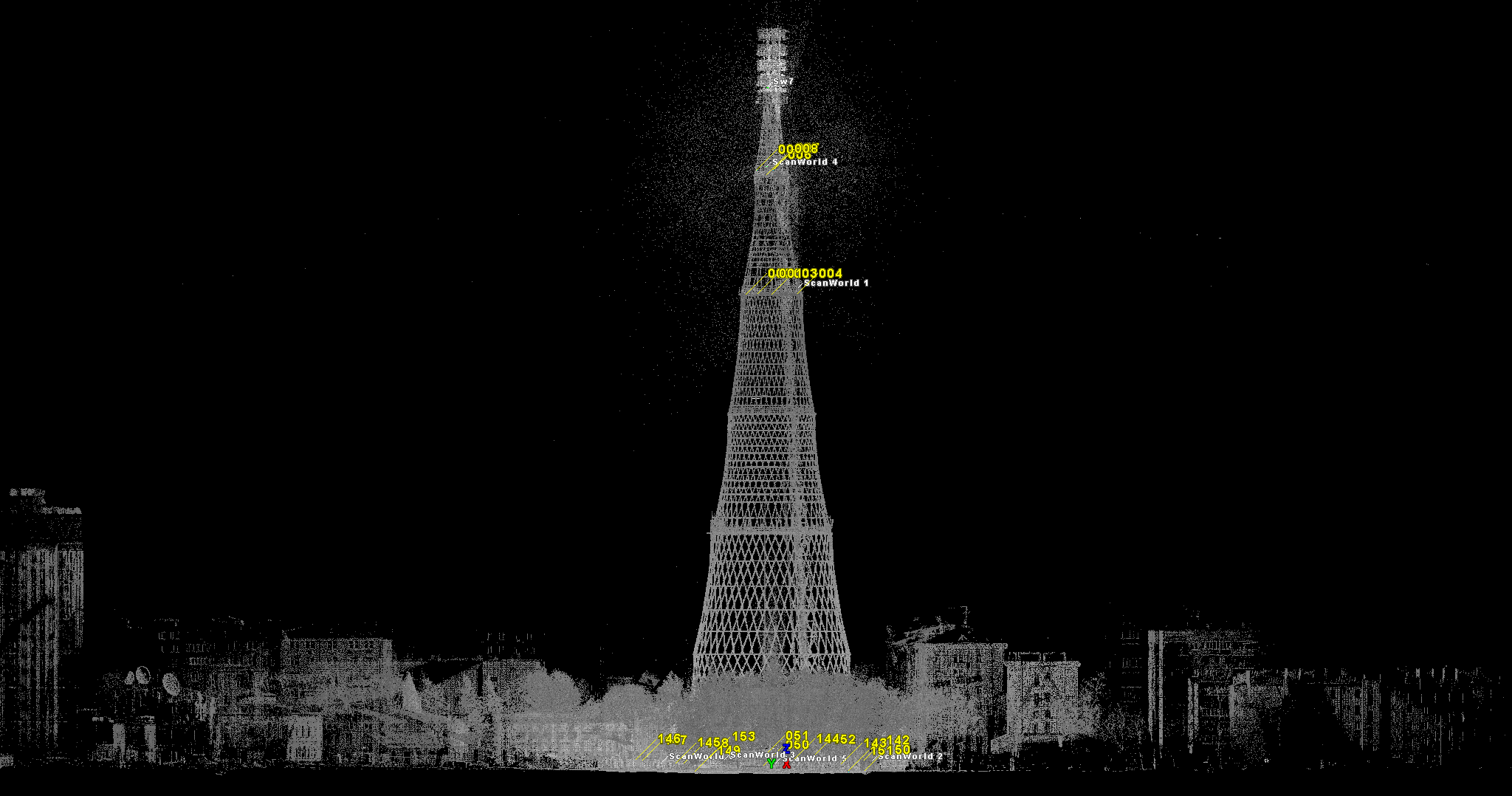

His final tower was nonetheless 160 metres tall and it supported the broadcast equipment of Soviet TV for 30 years and radio for much longer. Unfortunately, renovation was never a serious concern for the propaganda institutions so corrosion of the steel structure reached dangerous levels by 1991. Now, thanks to an international campaign, the government funding was finally provided to save the tower. At the time it was built, one of the inspirational features was the telescopic construction method. The renovation of the top four sections will involve a reversal of this process to dismantle the sections and then a complete overhaul and repositioning to restore the tower to its original 1922 state.

Before the renovation work started, the Russian Academy of Sciences decided to make a precise digital 3D model of the original tower. The work was assigned to the

Center for the Virtual History of Science and Technology and 3D specialists Trimetari Consulting who carried out the scanning work with the support of the FARO distributor

Master Service. The work began with a 3D scan of the whole tower in the middle

of the Russian winter. 3 days of laser scanning were carried out in December 2011 and equipment used included a FARO Laser Scanner Focus3D.

“Seven scanner stations were established – four at ground level, and three on the tower platforms,” explains Michael Anikushkin, CEO Trimetari Consulting. The final data set contained about 100 million points referenced to a fixed position at the tower base

and the Moscow Geodetic system. The mutual orientation precision of all the scans was 7 mm. Having created a full 3D digital model of the current state of the tower, the next step will be to model the whole lifecycle of the tower based on available documentation and then to create a virtual 3D story about this inspiring monument.

“We are an independent service provider and we support our customers with various brands of equipment. On this job we had a long-range pulse-based scanner and the FARO Laser Scanner Focus3D. Both were suitable at the lower stations, but only the Focus3D was small enough to be taken up the ladder to the scanning station at 141m. There was very little space up there and no protection from the weather. The light, compact and easy to use FARO Focus3D, really made the difference. Without it, we would not have been able to complete this job,” says Anikushkin thankfully.

The FARO Laser Tracker ION – our star in Baku!

The Crystal Hall in Baku, the largest city on the Caspian Sea and of the Caucasus region, has a total capacity of 25,000, and roughly 18,000 people will have seats for the event. The huge construction of the venue has to meet strict international requirements for holding large cultural and sporting events. In just a couple of weeks Baku will present the breath-taking indoor arena designed not only for the Eurovision Song Contest 2012, but for a long-term use as a venue for various events.

The complex building consists of three major elements: the modular NÜSSLI Group stadium®, interior roof and an elaborate exterior façade. A total of ca. 8,000 tonnes of steel is being used. These three elements are being planned, pre-assembled and installed at the same time. The building, which is the size of a football stadium, has been designed as a pure steel construction. The outer shell will give the building a crystalline look, backed up by an enormous amount of 80,000 LED lights.

While Roman Lob was making his way to the front line on German’s TV contest in February 2012 to represent the country in Baku with the song “Standing Still” in May, ALPINE Bau Deutschland AG and the NÜSSLI Group had already found their own star for Baku: Their vote went to FARO’s Laser Tracker ION as the best-in-class large volume measurement device for this prestigious project.

The extremely accurate, portable 3D measurement system the FARO Laser Tracker ION, with FARO’s software CAM2 Measure 10 and corresponding accessories, won the companies over with its excellent price-performance ratio. Users were given extensive training directly on site.

In this complex project enormous welded steel constructions have been tested against CAD data. Various factors have been precisely checked, e.g. hole patterns, lengths and angles. After all, when the venue is assembled in Baku, all the pieces must fit together perfectly. There is no time to redo any work during assembly.

The world’s most accurate large volume FARO Laser Tracker ION has a range of 110 metres (in diameter) and accuracy of up to a few hundredths of a millimetre. The speed of the laser beam in capturing data, no requirement for the warm-up of the laser tube, the self-compensation function as well we integrated precision level greatly speed up the measurement process.

Construction and assembly of Baku’s Crystal Hall already began in winter. Many measurements taken at this early phase of the project have been proved essential for the whole construction. The audience of the Eurovision Song Contest 2012 will soon be able to have a look into the interior of the already installed Baku Crystal Hall and admire the amazing illuminated outer steel façade.

Leibniz University of Hanover: 3D Documentation of the 1200 m2 steel and glass structure roof

If three-dimensional measurement of structures has been very complicated, expensive and error-prone up until now, then data collection with the latest generation of 3D laser scanners is now easy, accurate and rapid. These can be used to completely and accurately convert entire buildings and their fittings into digital models. Current scanners record up to one million measuring points per second: This means that surfaces up to a distance of about 50 meters can be reproduced in detail and at high resolution. The extremely small deviations of about 0.1 percent lie within the required DIN tolerances for construction.

-kopie.jpg?sfvrsn=0)

Now the scan data can be easily edited by the end user, because the computer hardware has become more powerful and because direct CAD import has become possible thanks to AutoDesk’s point cloud engine for AutoCAD and Revit Architecture. This eliminates expensive external processing of the data, so that the costs drop to a level similar to that of classical dimensioning. Thus the current niche existence of 3D documentation is now a thing of the past in many application areas: Laser scanning will revolutionise the current use of survey data!

Spatial building models have a number of advantages compared to traditional 2D surveys. As all the information in a spatial model is available in three dimensions, multifunctional applications are possible. This ranges from simple measurement and area calculations to stereoscopic navigation in virtual buildings. Because the scanner records all the visible structures of buildings and components, this results in completely seamless records that can be used across various disciplines. Information that is not needed for the particular application can be deleted in order to reveal important details and keep file sizes small.

The areas of use are extremely diverse; everywhere where the precise geometric investigation of the environment and rapid visualisation of the same are needed, optical 3D measurement using the latest laser scanning technology is impossible to beat:

Survey documentation of objects for

Plant engineering: modifications to installations and production lines

Architecture: monument protection, renovation planning, quantity surveys

Civil engineering: traffic structures, volume determination in open pits

Recording and digitisation in the areas of

Shipbuilding: CAD import of free-form surfaces

Reverse engineering: 3D modelling in CAD after scanning a prototype

Quality management: production analysis of e.g. wind turbines

Transfer of the scan data in virtual reality applications for

Forensics: location- and time-independent crime scene analysis

Film business: location scouting und computer-generated sets

Urban development: 3D city models and virtual flights

The project

Re-glazing was carried out using aluminium profile construction with highly insulated Schüco elements as part of the energy-related renovation of the glass roof over the listed courtyard of the Guelph castle. This is supported by the steel structure spanning the courtyard, with an area of around 1200 m2. The survey documentation of the spatial support structure, made of steel tubing and double I beams, were too old and imprecise to provide all the necessary measurements. After intense consideration, the company in charge of the project chose Langenhagen-based Masche Metallbau to carry out surveying with 3D documentation. This service was provided by architect J. Rechenbach and his Laser Scanning Architecture office. To do this, the steel substructure was measured in three dimensions in 12 individual scans; the scan data were then transmitted to the in-house CAD department for the planning work.

Using this procedure, it was possible to generate the 3D digital image of the complete geometry and pass it on within two working days. The laser scanner was on site for only 3 hours. Manual measurement would have taken about 40-60 hours of work, but without the assurance that every dimension had been determined to the last detail. These numbers show that the 3D documentation method is not only accurate and rapid, but also very economical!

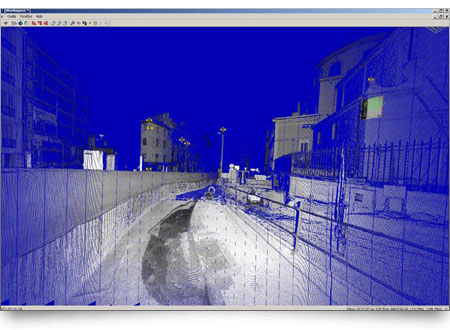

Visualisation of the 3D point cloud using FARO SCENE and AutoDesk Navisworks

Clear visualisation was implemented using various software solutions. First, the FARO SCENE software provides a photo-realistic display mode for the recorded data; in addition, the scan was also read into AutoDesk Navisworks. This makes it possible to combine the data from the laser scan with 3D data from other sources.

This allows a comparison of target and actual values to be carried out, in which the scan data are presented superposed on the newly created CAD plan so that deviations immediately become visible. Planning errors could thus be systematically avoided early on, thereby optimising the construction process. In this case, the faulty production of a single large aluminium-glass element would have been more expensive than the entire 3-D measurement of the object!

AutoCAD Architecture as an optimal tool for further use of the data

The detailed drawings were made in Masche Metallbau’s CAD department in 2D mode

using AutoCAD Architecture. To do this, the 3D point cloud model was “sliced” randomly to show the true geometry of the steel substructure at the desired position and to plan the glass elements of the roof accordingly. The freely available plug-in from AutoDesk, Cloud Point Extraction, was applied directly in AutoCAD. As a result, the complex 3D model can be reduced to any 2D content quick as a flash. The process is very intuitive and simple. This allowed all the desired measurements to be made and the 2D details to be worked out rapidly.

Transfer to SchücoCA D based on AutoCAD Architecture

Once the basic geometry had been determined and the axis spacing of the support points had been specified, the component library of the Schücad software was accessed in order to incorporate the profiles to be constructed in detail in the CAD planning.

Conclusion

The successful completion of the construction project now documents how accurately the digital surveying data are and what great benefits 3D documentation technology offers for construction applications in surveys and architectural monument preservation. 3D documentation precisely portrays the asbuilt condition especially in more complex geometries and older buildings in which deformations may have occurred, thus offering a high degree of planning reliability for an optimised construction process.

FARO Technologies, Inc. (NASDAQ: FARO) develop and market computer-aided measurement systems and software worldwide. The portable coordinate measuring devices from FARO®, together with their industry-specific software solutions, allow highprecision 3D measurements and 3D comparisons. They are used for inspecting components and component assemblies, production planning, and inventory documentation, as well as for the investigation and reconstruction of accident sites and crime scenes. They are also used for digital scanning of historical sites. The FARO Focus3D laser scanner is ideal for the three-dimensional documentation of buildings and building inspection, reverse engineering, monument preservation and forensic crime scene documentation – thanks to its simple operation and compact design, it can be intuitively operated using a touch screen and used for various applications: Indoor surveying documentation with the Focus3D, accurate 3D documentation of

indoor spaces and technical facilities, such as building equipment, conveyor systems or process equipment, can be created in a short time. Product and component documentation Whether for the quality control of large machine parts, for product design or for reverse engineering – the Focus3D measures products and components of any shape and size and then creates precise data and three-dimensional surface models. Outdoor surveying documentation The Focus3D is well suited for the 3D documentation of buildings, construction sites, roads and natural features. Objects at a distance of up to 120 m are recorded.

Your partner for 3D documentation and survey documentation in construction The Hanover-based architectural firm of qualified engineer Johannes Rechenbach specialises in laser scanning services and building documentation as the basis for planning modifications and the preservation of evidence. The evaluation options for optical 3D measurement range from colour 360° panoramas that can also be posted online to vectorised 2D plan drawings to 3D CAD drawings with intelligent component objects. There are therefore numerous possible formats in which the results can be transferred to the customer, depending on the requirement that has been agreed upon:

– Colour 360° panoramas of the construction project and its integration into the environment allow visual analysis of structural details up to the urban context. Even distance measurements and area calculations can be performed. These data are available online worldwide within one day to a freely selectable group of users.

– Thanks to the easy integration into AutoDesk products such as AutoCAD, the scan data can be transferred to the client for further processing; alternatively, “lsa” can generate the desired 2D drawings in dwg format. Floor plans, sections and views at any point of the building can be extracted from the digital scan model.

– The new point cloud engine in Revit Architecture has made the 3D modelling of the scanned object with integration into the Building Information Modelling Process possible. This means more effective planning processes, from early 3D visualisation to accurate component and mass determination to an inclusive planning process in which all participating planning specialists, such as structural engineers, building engineers and facility management, can work on the same building model without losses in communication. The added value of 3D documentation by our architectural firm is that, if required, the owner is provided with comprehensive support of their property, from digital measurement to planning and construction. If only surveying is commissioned, we can provide statements regarding the quality of the structural fabric and proposals for energysaving renovations as part of the scan analysis. We have the same perspective as our clients, who also come from the construction industry. Laser Scanning Architecture: We make sure that your architecture gets to the point.

Contelos GmbH Your AutoDesk Gold

Partner in the North Founded in 1992, Contelos GmbH, headquartered in Gehrden with an office in Bremen, is an industry-neutral consultancy and systems company that has consistently transformed itself into a system integrator and supervisor in all areas of AutoDesk over the past 10 years. Contelos GmbH is one of the few CAD industry specialists that provide a single source for the areas of architecture, construction, engineering and geographic information.

Contelos GmbH has also gathered extensive experience in various projects in building survey data collection with subsequent 3D modelling for use in the field of facility management. Contelos GmbH is happy to work together with your software customers in these projects. As a result, extensive projects can be brought to fruition effectively, economically and with high quality.

Technipipe diversifies its activities using a FARO Laser Scanner

Technipipe, a specialist in pipeline engineering, inspection and maintenance services, has won an international reputation for itself in the area of petroleum engineering. Its clients include many of the big names in the industry. Since they wanted to diversify their activities and open up new markets, Technipipe decided to enter the promising 3D laser scanning market and invested in the FARO 3D digitalization system: the FARO Laser Scanner.

Technipipe offers specialized engineering, inspection and maintenance services for pipelines. Since 1990, the company has basically specialized in offering services to operators of pipelines for industrial fluids (petrochemical, chemical and gas companies). Originally based close to the petroleum and petrochemical industries near Marseille, Technipipe soon extended its activities all over France. Using its experience in dealing with problems connected with the operation of pipelines, Technipipe rapidly branched out into project management and engineering for rerouting and overhauling pipelines, as well as projects to lay pipelines of short to medium

length. In addition, Technipipe regularly carries out design studies associated with pipelines: scraper stations or feasibility of scraping operations, as well as safety and risk studies. Technipipe’s reference list includes many of the big names in the industry, such as Air Liquide, Arcelor, BP France, EDF GDF, SNCF – TGV, Total etc. Technipipe also boasts expertise in the

areas of topography, cathode protection, pipeline inspection, and network monitoring, and wished to add 3D laser scanning to its portfolio of services. For this reason, in 2007, the company acquired a powerful 3D digitalisation system, the FARO Laser Scanner. With the acquisition of this new system, Technipipe is now in a position to offer 3D surveys using a precision

technology based on laser scanning.

In a matter of minutes the local environment is captured in the form of a point cloud, each point accurate to the nearest millimetre, with a large range. The FARO Laser Scanner is a digitalisation system that employs laser technology. It executes a precise 3D survey of objects or of large interior spaces by sweeping through 360° and digitising everything that it encounters up to a distance of 120 m away in its line of vision. It captures millions of 3D measurements at a

rate of 976,000 points/second and can generate complete 3D colour images in very little time, with each pixel being assigned XYZ coordinates that can be processed with FARO Scene, the program supplied with the device. The scan data means that it is then possible to perform direct measurements within the point cloud, to carry out analyses and to generate precise CAD models. Technipipe can thus measure distances, carry out planar studies and export the resulting scanned point cloud to Rhinoceros and Catia software. Laser scanning means that the surveyed environment can be accurately reproduced in 3D by processing the captured

point cloud. The 3D model can be exported to the following programs: AutoCAD, Microstation,

Catia, 3D Studio and SolidWorks. After 3D modelling, it is possible to create sections

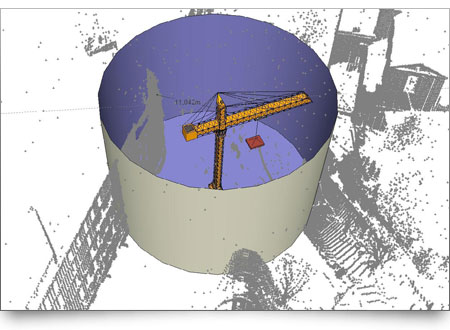

and perform conformity checks and risk analyses in the various areas of application, such as in the petrochemical industry, civil engineering, 3D archival or heritage inventorying. For example, Technipipe used the Laser Scanner to perform a preparatory study for the installation of a crane on a town centre site. One of its clients, a civil engineering company, planned to erect a crane there and wanted to study the available space with respect to the span and height of the crane. In a town centre, particularly because of safety restrictions, the rotation of the crane is limited by the buildings that surround the site. For this reason, the positions of the ridges of the surrounding buildings, the trees and the electricity poles must be known and mapped to determine the points where the crane should be fixed.

Numbered points were therefore identified on the scan corresponding to the key points to be recorded as coordinates, in order to verify the feasibility of the installation of the crane. All the points scanned to the 3D laser were georeferenced, i.e. the position of each point in the scan

is fixed in the Lambert coordinate system: the position in terms of X, Y and Z coordinates

(elevation, sea level->Z=0). The capture of different 3D views allows a multitude of details to be identified from several angles, for example the road junction next to which the site is located. These different views not only enable the scene of activity to be ’photographed’ in 3D but also

to locate the key points on the buildings and to visualize them very clearly. As the lengths are recorded and the precise coordinates of each point are known, it is possible to carry out supplementary measurements at the office without having to return to the site. This system offers a considerable saving in time, simplicity of operation and sufficient accuracy for this type of application. In this case, simply finding the XYZ coordinates of the critical points was enough

to position the points on an existing AutoCAD plan. All that remained to be done in Auto- CAD was to draw a circle with a radius equal to the span of the crane and check the intersections

with the XYZ coordinatesof the surveyed points.

Planar view of the area around the site where the crane is to be installed

4 good reasons

A portable non-contact measurement system using laser technology to accurately capture measurements. The system rotates 360° and automatically measures everything within the line of sight from the scanner´s position.

Optical Measurement: The intelligent laser system carries out optical non-tactile measurements.

Resolution: The scanner creates an image with an extremely high resolution of up to 711 mio. pixel per scan.

Measuring Volume: The laser scanner captures measurements within a spherical radius range of up to 120 metres.

Portability: With a weight of 14.5kg the laser scanner is easy to transport.

Documenting Architectural Façades with the Laser Scanner

“The FARO scanner was chosen to perform these scans because of its ability to scan from a significant distance and produce accurate data,” SightLine president Penny Anstey

Renovating historical landmarks requires a careful balance between preserving the architectural elements that characterise the generation of the original build while updating items to support modern life.

Thus was the burden consultants faced when designing plans for a $30 million restoration of the Northwestern Mutual Life building in Milwaukee (USA). Constructed in 1914, the Marshall & Fox-designed neoclassical building boasts ten 74-foot high, 422-ton columns with Greek Corinthian treatments, and is crowned by a majestic granite cornice. Restoring the cornice was key to the historical preservation of the building. Having been built before the age of computers and CAD programs, the first step of the restoration required obtaining digital as-built documentation of the cornice.

Local consulting firm, SightLine, LLC, was charged with the task of gathering the measurements from the centre points along the cornice of the building. Bridging the gap between innovation neoand tradition, SightLine utilised laser scanning technology to generate the measurements necessary to restore the classic beauty. SightLine collected the measurements with the FARO Laser Scanner. “The FARO scanner was chosen to perform these scans because of its ability to scan from a significant distance and produce accurate data,” said SightLine president Penny Anstey.

The Laser Scanner builds a 360 degree point cloud of a scanned surface by sending an infrared beam into the centre of a rotating mirror. Using encoders to measure the mirror rotation and the horizontal rotation of the laser scanner, the X,Y,Z coordinates of each point can be registered and modeled. SightLine completed the survey of the cornice in four days. The Laser Scanner afforded SightLine the luxury to safely collect the scans 150 feet away, within an accuracy of less than a 1/10 of an inch. All measurements were completed without erecting any scaffolding or dropping swing stages over the side of the building. “Almost all of the data was collected from the ground,” Penny Anstey observed. “The contractor seemed to think the equipment was magic because it could produce a point cloud view as fast as it was being scanned.” SightLine overcame any line-of-sight issues by strategically placing registration spheres or targets around the scanner and the building.

The scans were taken from different viewpoints on the ground and roof top and linked by the spheres within the FARO Scene software. The clear-view representation of the linked information produces a visualisation similar to that of an x-ray. The effect left the contractor with the impression that the laser scanner could scan through walls.

The scans were taken from different viewpoints on the ground

and roof top.

THE DATA

Sightline selected portions of the 3D point clouds, and through viewing the cloud in various directions, they traced the items in AutoCAD Architectural Desktop to generate line drawings. They produced 16 sets of digital 2D drawings of the cornice and building profile. The scans revealed that the original design drawings did not match what was actually built. An entire wing of the structure extended out further than the other, something that was not noticeable to the human ,eye. Once the contractor saw the detail generated by the scans, he requested additional

information about the building. SightLine provided elevation studies and details on sections through typical areas (such as window bays) and ornamental architectural elements. More deviations were discovered. While the existing drawings documented finials as stylized acorns, the scans revealed that they were actually barley hops. SightLine was able to provide the information without revisiting the actual site, due to the immense amount of data collected during the initial scanning. Therefore, generating the additional information was only a matter of software management.

ROI

“We feel that laser scanning has an endless amount of potential and would benefit anyone in time savings, error reduction, and added safety,” stated Penny Anstey. The rapid rate of collection, ease of data capture, and accuracy of measurements were major factors that influenced SightLine to employ laser scanning techniques versus traditional survey methods. Using the former method to gather measurements could have taken months, considering that a large amount of scaffolding would need to be erected,” stated Penny Anstey. “Not to mention the fact that if workers had missed anything, they would have to keep going back to the site to collect data. And who is to say that the data would have been accurate?”

ABOUT SightLine

SightLine applies the use of 3-dimensional laser scanning technology for a variety of documentation purposes. They provide clear and accurate records of conditions for both new and preexisting structures.

About FARO

With more than 20,000 installations and 9,500 customers globally, FARO Technologies, Inc. designs, develops, and markets portable, computerized measurement devices and software used to create digital models – or to perform evaluations against an existing model – for anything requiring highly detailed 3-D measurements, including part and assembly inspection, factory planning and asset documentation, as well as specialized applications ranging from surveying, recreating accident sites and crime scenes to digitally preserving historical sites.

5 good reasons

Broad flexibility: the Laser Scanner is portable, light and compact and allows large volumes to be digitised rapidly and precisely, including places which are difficult to access.

High precision: the Laser Scanner offers precision in a range from 2mm up to 25m.

Extreme range: dependingm on the model, the measurement range can extend up to 120m, which is the furthest range a 3D scanner using phase shift technology can attain.

By using the digital camera (as an option) with the Laser Scanner, you can obtain high-resolution colour scans with more than 700 pixels per scan.

FARO offers a complete range of accessories (as options) which can assist you in all your projects: carbon fibre tripod, backpack for transport, carrying handle, batteries, etc.

A solution to toughest inspection challenge – 3D inspection in the metal industry in the MENA-region

Saif Al Midaf Director General, Expo Center Sharjah

There is a solution for your toughest inspection challenge. FARO’s portable 3D measurement systems offer a solution for almost every inspection challenge in the metal industry.

Today, approximately 10,000 customers worldwide with more than 20,000 installations have put their trust in FARO measurement systems. They can be found in the production and quality assurance processes of leading companies such as ABB, Airbus, Audi, Boeing, BMW, British Aerospace, Daimler, Ford, Goodyear Dunlop, Hewlett Packard, Honda, Johnson Controls, MAN, Miele, Porsche, Siemens, SKF, and Volkswagen. Most of the companies mentioned above, or at least their suppliers, have opened facilities and offshore offices in the Middle East region for many reasons: firstly because of the energy and low-cost of manpower; secondly because of the good infrastructure especially in UAE and Qatar, where a huge improvement in the infrastructure conditions happened in the last couple of years. The improvement in the infrastructure means: new runways, expansion of airports and harbours, and in some countries new railways or metro like the one recently opened in Dubai. All that infrastructure improvements mentioned above utilise steel and metal construction. If we look to the modern architecture in the MENA-region we find steel glass building are increasing especially in the >>gulf region, the most impressive one is Burj Khalifa, which is the highest building worldwide

with 824 m.

3D inspection![]()

The portable coordinate measuring devices from FARO, together with their industry-specific

software solutions, allow high-precision 3D measurements, 3D comparisons and inspection

of parts and complex systems directly within assembly and production processes in the

metalworking industry. FARO reinvented measuring: instead of carrying parts to the measuring machine FARO’s systems can be deployed just where the most accurate measurements are

necessary. They are used for inspecting components and component assemblies, production planning and inventory documentation. FARO’s products perform 3D inspections of parts and assemblies to eliminate costly manufacturing errors, dramatically reduce on-site measuring time and increase productivity and profitability. FARO offers a comprehensive range of portable measurement solutions, from 0.00018” accuracy to 230 ft. range. One of the most important

topics in the steel and metal industry is inspection and verification of parts according to dimensional tolerances. Inspection of parts and providing a measurement report is an essential part of today’s lean manufacturing world. Quality standards are higher than ever reducing production waste and costs as well as non-conformance which can lead to production down time. The main advantage of using laser scanning technology is the timesaving, many thousands of points are captured every second meaning that parts can be rapidly reverse engineered and reproduced virtually. International customers who use FARO devices for inspection purposes state that the data capture is far faster using laser scanning technology compared to conventional documentation techniques. Also working with the actual data captured from the environment allows planners to incorporate deviations from original design plans in their rework of facilities, reducing the risk of clashes occurring during the installation of new features. This can significantly reduce project turnaround time leading to big savings.

Especially the metalworking industry which faces the challenge to measure and inspect

huge parts in 3D. Being able to do this with FARO’s portable measuring devices on site gives

the benefit of not having to move the part to an inspection tool. This saves both time and

transportation cost.

Construction boom

Saif Al Midaf, General Director of the Expo Center Sharjah, claims that the Middle East construction boom will continue being one of the major driving forces behind the regional steel

sector’s growth in the coming years. The demand in the region increased from 70 million tons in 2007 to around 90 million tons in 2010, according to industry sources. On daily basis FARO receive requests from this region for 3D measurement devices from different sectors but mainly from steel- and metal- as well as construction industry. Currently FARO has approximately 100

measuring devices in the Middle East and North Africa supporting the toughest and most complicated projects. FARO’s measurement systems in this market were either ordered directly at FARO or through FARO’s distributors in the region in e.g. Egypt, Israel, Pakistan, Saudi Arabia, Tunisia & Algeria.

About FARO

FARO develops and markets computer-aided coordinate measurement systems and measurement software worldwide. The portable measurement equipment from FARO

permits high precision 3D measurements and 3D comparisons of parts and complete

systems within production and quality assurance processes. They are used for inspecting components and component assemblies, production planning, and inventory documentation. Today, approximately 9,500 customers worldwide with more than 20,000 installations have put

their trust in the FARO systems.

4 good reasons

With a very high measuring precision the FARO Laser Tracker is the most precise tracker measurement system on the market.

Xtreme ADM: The laser beam can be “intercepted” again in the air at any time so that measuring can be continued without delay. This is very helpful, especially in barely accessible areas.

Instant-on: The laser tracker doesn’t require a warm-up phase.

Smart Warm-up: The broad range of working temperatures combined with temperature compensation to enable operation in almost any environment.

SelfComp: Automated compensation (re-adjustment of encoder) guarantees that the system measures with maximum precision even under difficult conditions.